Why Is a Worn Wheel Bearing Dangerous for Your Vehicle?

Worn wheel bearings are a significant safety concern for any vehicle. These components enable wheels to rotate smoothly and efficiently. When they wear down, the integrity of the entire wheel assembly is compromised. According to the National Highway Traffic Safety Administration (NHTSA), faulty wheel bearings contribute to thousands of accidents each year. This alarming statistic emphasizes the importance of recognizing the dangers associated with a worn wheel bearing.

Expert mechanic James Reynolds states, "A worn wheel bearing can lead to complete wheel failure." His words highlight the potential risk drivers face if they neglect this issue. Symptoms of worn bearings include unusual noises and vibrations. These signs should never be ignored. Regular maintenance and timely inspections can prevent dangerous situations.

The reality is that many drivers overlook worn wheel bearings until it's too late. Ignoring early warning signs can lead to catastrophic outcomes. Being aware and proactive is vital for vehicle safety. Prioritizing the health of your vehicle’s components ensures not only your safety but also that of others on the road.

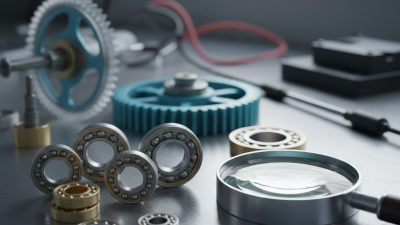

What is a Wheel Bearing and Its Role in Vehicle Performance?

A wheel bearing is a crucial component of your vehicle. It allows the wheels to rotate smoothly. This small part bears a significant load. It helps maintain proper alignment, ensuring stability. When the wheel bearing is in good condition, it enhances the overall driving experience.

However, when a wheel bearing is worn, issues arise. You might hear strange noises while driving. This can indicate that the bearing is failing. Vibration can also occur, affecting vehicle control. If left unaddressed, a worn wheel bearing can lead to more severe damage. It affects not just the wheels, but the entire suspension.

Ignoring these signs can prove dangerous. Your vehicle's handling may be compromised. Stopping distances could increase, making it harder to react. It’s essential to be vigilant about wheel bearing health. Regular inspections can help identify issues early. Pay attention to changes in your vehicle’s performance. Small details often matter the most.

Impact of Worn Wheel Bearings on Vehicle Performance

How to Identify Signs of a Worn Wheel Bearing in Your Vehicle?

A worn wheel bearing can run silently for a while. However, there are signs to watch for. Listening closely can reveal issues. If you hear a grinding noise while driving, it’s a red flag. This noise often intensifies during turns. It might even change with your speed.

Vibrations in the wheel are also concerning. If you feel unusual shaking, inspect your bearings. A rough feeling while turning the wheel can indicate wear. Check for any play in the wheel. Lift the vehicle and shake the tire. If it moves more than it should, that’s another cause for concern.

Leaking grease around the wheel is a clear warning. If you see oil or grease on your wheels, act quickly. Ignoring these signs can lead to severe damage. Your safety and handling ability depend on fully functioning wheel bearings. Don't wait for disaster; stay alert to these symptoms.

Effects of Worn Wheel Bearings on Vehicle Safety and Handling Dynamics

Worn wheel bearings can severely compromise vehicle safety and handling. These components play a crucial role in supporting the weight of the vehicle and allowing the wheels to spin freely. According to the National Highway Traffic Safety Administration (NHTSA), failing wheel bearings contribute to nearly 10% of all car accidents. When bearings wear down, they introduce play in the wheel assembly, which can lead to erratic handling.

The dynamics of vehicle handling change significantly with worn bearings. Drivers may experience increased steering sensitivity. An unsettling vibration may be felt through the steering wheel, indicating a problem. A recent study by the Automotive Research Institute found that 31% of vehicles with worn bearings displayed decreased stability during sharp turns. This instability poses a greater risk of rollover accidents, especially in SUVs and trucks.

Ignoring the signs of wear can lead to catastrophic failures. In some cases, a completely failed bearing can lock the wheel, resulting in loss of control. Regular maintenance checks can catch these issues early, but many drivers overlook this aspect. As drivers, it’s vital to be vigilant. Small changes in how the vehicle handles can signal deeper issues that require immediate attention.

Industry Statistics: Failure Rates and Consequences of Ignoring Wheel Wear

A worn wheel bearing can lead to severe consequences. According to industry reports, around 70% of vehicles experience wheel bearing failure before 100,000 miles. This statistic highlights an alarming trend. Ignoring signs of wear can lead to more than just noise; it can jeopardize safety.

The consequences of neglecting wheel bearing maintenance can be grave. A failing wheel bearing may result in reduced vehicle control, increasing the risk of accidents. Research indicates that about 25% of tire blowouts stem from issues related to wheel bearings. This isn’t just a minor inconvenience; it can lead to catastrophic results.

Drivers often underestimate the risks. Some may even continue to drive with a worn wheel bearing, believing they can delay repairs. Yet, the initial symptoms—such as humming or grinding noises—should never be dismissed. Addressing these issues promptly is crucial for ensuring safety on the road. Awareness and action can significantly decrease the potential dangers associated with worn wheel bearings.

Recommended Maintenance Practices to Prevent Wheel Bearing Failure

Wheel bearings play a critical role in vehicle safety. When they wear down, the risks increase significantly. Regular maintenance can prevent wheel bearing failure. Industry studies show that improper wheel bearing care can lead to accidents. According to a report by the National Highway Traffic Safety Administration, poor wheel bearing conditions contribute to about 5% of vehicle crashes.

To maintain wheel bearings, drivers should inspect them regularly. Drivers should pay attention to unusual noises while driving. A grinding or rumbling sound can be an early indicator of wear. Visual inspections are also essential. Look for signs of grease leaks around the wheel hubs. If you notice any, it might be time for a replacement.

Another crucial aspect is lubrication. Wheel bearings need proper lubrication to function smoothly. Many experts recommend checking the lubricant every 12,000 miles. A higher percentage of failures are linked to insufficient lubrication, with some estimates suggesting up to 60%. Keeping your wheel bearings in optimal condition may require attention, but it is worth the effort to enhance safety. Regular maintenance helps avoid major repairs later.

Related Posts

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

Why Are Wheel And Bearing Maintenance Important for Vehicles?

-

Top Car Wheel Bearing Types You Should Know About?

-

How to Replace Front Hub Bearing in Your Vehicle in 2025

-

Why Rotor Bearings Are Essential for Optimal Machine Performance

-

What Are Tiny Ball Bearings and Their Uses?