Top Car Wheel Bearing Types You Should Know About?

When it comes to car maintenance, understanding car wheel bearings is crucial. Expert mechanic John Smith emphasizes, "A quality wheel bearing can make all the difference in vehicle performance." Every car owner needs to grasp how these components function.

Car wheel bearings support the weight of your vehicle while allowing smooth wheel rotation. Different types exist, each with unique features. For instance, sealed bearings prevent dirt and moisture from entering but may be more expensive. Conversely, non-sealed bearings are easier to maintain but can wear out quicker.

Many drivers overlook their importance. Ignoring signs of wear can lead to costly repairs. Regular checks can prevent major problems down the road. Recognizing the types and their functions ensures safer driving and better vehicle longevity. Exploring the various types of car wheel bearings will enhance your automobile knowledge and empower you to make informed choices.

Understanding Wheel Bearings: Definition and Function in Vehicles

Wheel bearings play a crucial role in vehicle performance. They are essential components that allow the wheels to rotate smoothly. Situated between the wheel hub and the axle, they reduce friction and support vehicle weight. Without them, driving would be a jolting experience.

There are various types of wheel bearings. The most common ones include tapered and ball bearings. Tapered roller bearings handle heavy loads well, making them ideal for trucks. Ball bearings are more common in smaller vehicles and offer decent performance. Yet, not all bearings are equal. Some may degrade faster, causing early wheel wear. It's essential to choose the right type based on your needs.

Routine maintenance is key. Checking for signs of wear can prevent costly repairs. Listen for unusual noises while driving. Vibration may indicate a bad bearing. Neglecting these signs can lead to more severe issues down the line, so a proactive approach is vital.

Top Car Wheel Bearing Types You Should Know About

| Bearing Type | Description | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Ball Bearing | A type of rolling-element bearing that uses balls to maintain the separation between the bearing races. | Passenger vehicles, bicycles | Low friction, high speed capability | Limited load capacity compared to other types |

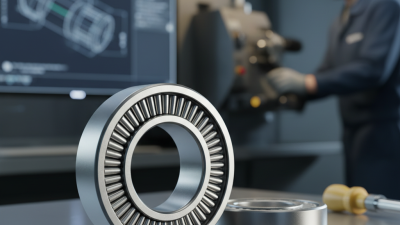

| Roller Bearing | Uses cylindrical rollers to support radial loads and can handle heavier loads than ball bearings. | Trucks, heavy machinery | Higher load capacity, durability | Higher friction, limited speed |

| Tapered Roller Bearing | Designed to support both radial and axial loads and has cone-shaped rollers. | Heavy-duty vehicles, trailers | Handles high axial loads, self-aligning | More complex design, requires precise installation |

| Angular Contact Bearing | Designed to support both radial and axial loads in a specific direction. | High-speed applications, automotive races | Higher load handling, better rigidity | Can only handle axial loads in one direction |

| Self-Aligning Bearing | Features two rows of rollers that are held together by a common spherical outer race. | Industrial machines, agricultural equipment | Can accommodate misalignment, easy handling | Lower load capacity compared to other types |

Key Types of Wheel Bearings: Ball Bearings vs. Roller Bearings

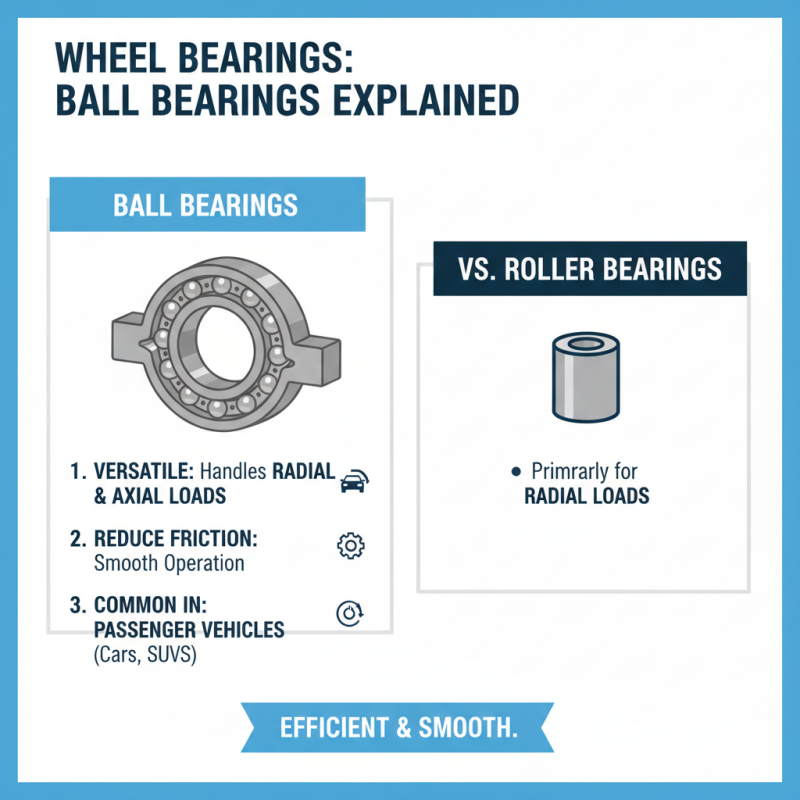

When considering wheel bearings, it’s essential to understand the differences between ball bearings and roller bearings. Ball bearings are versatile. They handle both radial and axial loads well. Typically, they consist of balls that reduce friction between moving parts. Research indicates that ball bearings are often used in passenger vehicles due to their efficiency and smooth operation.

On the other hand, roller bearings excel in heavy-load applications. Their cylindrical shape allows them to support greater loads, making them suitable for trucks and heavy machinery. According to a recent industry report, roller bearings can withstand much higher stresses compared to ball bearings. However, they may require more maintenance and be less effective in lower load situations.

Tips: Always consider the environment where your vehicle operates. Dusty or wet locations can wear down bearings more quickly. Regular inspection can help catch issues early. If you notice noise or vibration, it's time for a checkup. Keep in mind, while ball bearings may seem preferable for light use, roller bearings shine in heavy-duty situations.

Lifespan and Maintenance: How to Extend Your Wheel Bearings' Life

Wheel bearings play a crucial role in your vehicle's performance. They allow the wheels to rotate smoothly. Proper maintenance is vital to their longevity. One way to extend their lifespan is lubrication. Regularly check the grease levels. If they are low, it could lead to increased friction. That can shorten your bearings' life dramatically.

Another critical factor is ensuring proper alignment. Misalignment can cause uneven wear. This issue can lead to failure over time. Drivers should also be aware of noise changes. Unusual sounds may indicate a problem. Ignoring these signs may result in costly repairs later. Inspect your wheel bearings during routine maintenance. This habit can prevent surprises down the road. Regular checks can save money in the long run.

Driving conditions can also impact bearing life. Rough roads and excessive speeds can accelerate wear. Be mindful of road quality during your travels. Taking care of wheel bearings means looking out for small issues early. Implementing these practices will help them last longer. Avoid overlooking these details. They can make a significant difference in performance.

Signs of Wheel Bearing Failure: What Every Driver Should Notice

Wheel bearings play a crucial role in vehicle safety. They help wheels rotate smoothly and support the weight of the car. However, when they start to fail, drivers must be alert to specific signs. Listening carefully can save you from future headaches.

One common indicator of wheel bearing failure is a humming or grinding noise. This sound often increases with speed. Drivers should also notice vibrations in the steering wheel or vehicle. These sensations can signal that the bearings are worn out. If you feel these issues, it's better not to ignore them. Delaying could lead to more severe problems down the road.

Pay attention to any uneven tire wear. Sometimes, it’s subtle, making it easy to overlook. If you notice one side of the tire wearing down faster, it could be a sign of damaged bearings. Regular tire inspections can help catch these issues earlier. Being proactive in noticing these signs may seem tedious, but it can ensure road safety.

The Impact of Wheel Bearing Quality on Vehicle Performance and Safety

The quality of wheel bearings significantly impacts vehicle performance and safety. Poor quality bearings can lead to increased friction and heat. This can cause premature wear on tires and suspension components. Furthermore, subpar wheel bearings might fail unexpectedly, leading to dangerous situations while driving. It’s crucial for vehicle owners to be aware of the signs of wheel bearing issues, such as unusual noises or vibrations.

Regular checks on wheel bearings can prevent severe problems. If a bearing is worn, it can affect steering accuracy. This not only compromises handling but also increases braking distances. Many drivers overlook bearing maintenance, focusing instead on more visible components like brakes or tires. This oversight can lead to more significant repairs and safety risks.

Investing in high-quality wheel bearings is essential for longevity. However, there’s a misconception that all wheel bearings are the same. This belief can lead to underestimating the importance of proper installation and regular checks. A small issue can escalate, resulting in costly repairs and safety hazards on the road. Understanding the function and quality of wheel bearings can enhance your driving experience and ensure safety.

Related Posts

-

What is Rv Wheel Bearings and How to Choose the Right Ones for Your Vehicle

-

Why Are Wheel And Bearing Maintenance Important for Vehicles?

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

Top 10 Side Wheel Bearing Signs of Wear and Replacement Tips

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying