Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying

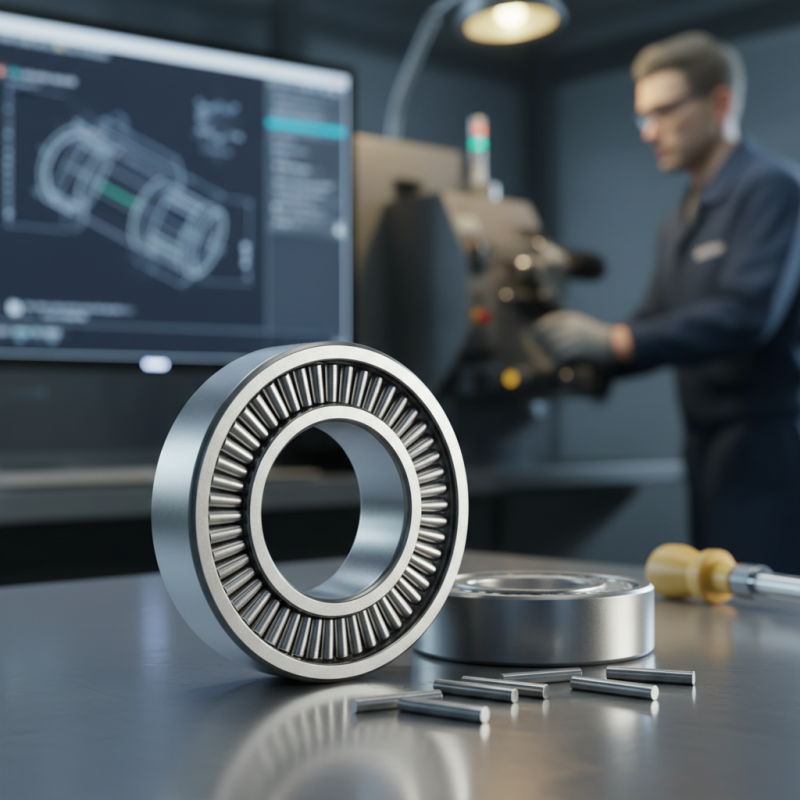

When it comes to precision engineering components, the Ntn Needle Bearing stands out as a preferred choice for many industries due to its exceptional performance characteristics. According to industry expert John Smith, a renowned mechanical engineer, “Ntn Needle Bearings are essential for reducing friction and enhancing the efficiency of machinery.” This statement encapsulates the essence of why understanding the benefits of these bearings is crucial before making a purchase.

Needle bearings are designed to handle heavy loads while maintaining low friction, which makes them an asset in applications where space is limited. Their unique structure allows them to accommodate both radial and axial loads, setting them apart from traditional roller bearings. In sectors ranging from automotive to aerospace, the reliability and durability of Ntn Needle Bearings become pivotal for operational success.

As more manufacturers seek to optimize their machinery for better performance and longevity, recognizing the advantages of Ntn Needle Bearings is essential. Whether you're involved in design, production, or maintenance, understanding the top benefits of these bearings will enable you to make informed decisions that elevate the efficiency and reliability of your equipment.

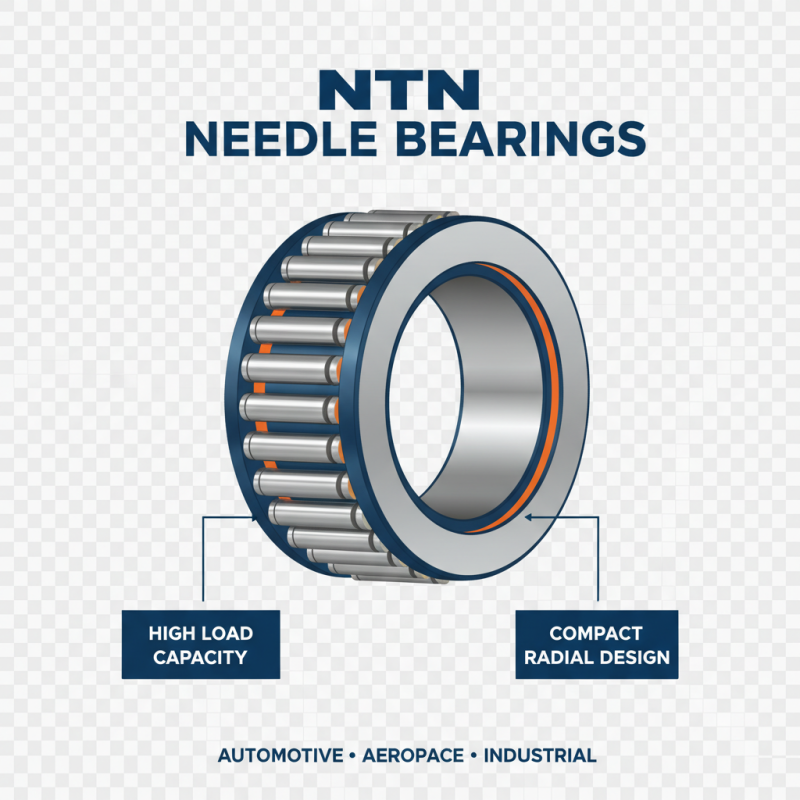

Understanding NTN Needle Bearings: An Overview of Their Design

NTN needle bearings are designed with a unique structure that sets them apart from traditional bearings, making them an essential component in various applications. Their design features long, thin rollers that provide a high load-carrying capacity while minimizing the radial space required. This compact design enables engineers to maximize efficiency in systems where space is a premium, such as in automotive, aerospace, and industrial machinery.

The arrangement of needle rollers within the bearing allows for reduced friction and increased durability, which is pivotal in extending the lifespan of machinery. Additionally, the superior surface contact of these bearings offers excellent performance under high speeds and harsh operating conditions. The integration of NTN needle bearings in equipment can significantly enhance overall performance by providing smooth operation and reducing noise, making them a preferred choice for precision applications. By understanding their design and benefits, users can make informed decisions that align with their specific engineering needs.

Key Advantages of NTN Needle Bearings in Mechanical Applications

NTN needle bearings have become increasingly vital in various mechanical applications due to their unique advantages. One key benefit is their ability to handle high radial loads while occupying minimal space. According to a report by the International Journal of Mechanical Sciences, needle bearings can support up to 60% more load than traditional rolling bearings, making them ideal for compact environments where space is a premium. This characteristic is particularly useful in automotive and industrial machinery, where performance and efficiency are paramount.

Another significant advantage of NTN needle bearings is their reduced friction properties. A study published in the Journal of Tribology highlighted that needle bearings demonstrate lower friction coefficients compared to other bearing types, resulting in enhanced energy efficiency and extended lifespan of machinery. This reduction in friction not only leads to improved operational performance but also decreases energy consumption, aligning with modern sustainability goals in manufacturing. As industries continue to focus on maximizing efficiency and reducing costs, the utilization of needle bearings stands out as a compelling solution for enhancing mechanical systems.

Durability and Longevity: How NTN Needle Bearings Perform

When considering needle bearings, durability and longevity are key factors that significantly influence their performance in various applications. Needle bearings are designed with elongated rollers that reduce friction, allowing for smoother operation and increased load-carrying capabilities. This unique design enables them to withstand high levels of stress and heavy loads, making them ideal for use in machinery and equipment required to operate continuously under demanding conditions.

Moreover, the materials used in the construction of needle bearings play a crucial role in their overall longevity. They are often made from high-strength steel, capable of resisting wear and tear over time. This resistance to abrasion ensures that the bearings maintain their integrity even when subjected to harsh environments or high temperatures. Additionally, proper lubrication can further enhance the lifespan of these bearings, minimizing the risk of failures and costly downtimes. Consequently, investing in high-quality needle bearings can lead to significant long-term savings due to reduced maintenance and replacement needs.

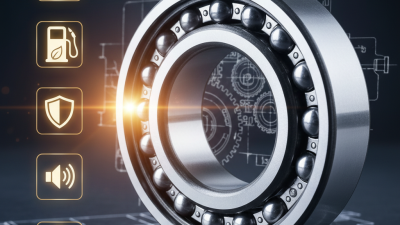

Operational Efficiency: Reducing Friction and Energy Loss

When considering the operational efficiency of machinery, the role of needle bearings cannot be overstated. These specialized components significantly reduce friction between moving parts, enabling smoother operation and minimizing energy loss. By utilizing a design that incorporates a series of thin, cylindrical rollers, needle bearings allow for a more effective load distribution, which in turn decreases the resistance encountered during movement. This characteristic is particularly advantageous in high-speed applications, where minimizing friction is vital for maintaining performance and longevity.

Moreover, the reduction of energy loss translates into lower operational costs. As machines run more efficiently, the overall energy consumption decreases, which not only benefits the environment but also enhances the bottom line for businesses. With needle bearings, operators can expect less wear and tear on equipment, leading to extended maintenance intervals and less downtime. This combination of reduced friction and energy efficiency makes needle bearings an essential consideration for those looking to optimize their machinery's performance and reliability.

Factors to Consider When Choosing NTN Needle Bearings for Your Needs

When selecting needle bearings for your machinery or applications, there are several crucial factors to consider to ensure optimal performance and longevity. First and foremost, assess the load capacity requirements of your application. Needle bearings are designed to handle specific load patterns, and understanding the radial and axial loads they will face is essential for making the right choice. A bearing that matches the load specifications will minimize the risk of premature wear or failure.

Another significant factor is the operating conditions of your application. Consider variables such as temperature, humidity, and exposure to contaminants, as these can significantly affect bearing performance. For environments with high temperatures or potential for debris ingress, selecting bearings with appropriate seals or lubrication methods is critical. Additionally, reviewing the speed ratings of the bearings is important, since exceeding these limits can lead to overheating and operational issues. Ultimately, a careful analysis of these factors will guide you in choosing the most suitable needle bearings for your specific needs, ensuring both efficiency and reliability in your operations.

Top 10 Benefits of NTN Needle Bearings

Related Posts

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

What is a Front Axle Bearing and How to Choose the Right One

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

Top 5 Benefits of Using High Quality Transaxle Bearings for Your Vehicle