Top Tips for Maintaining Your Wheel and Bearing Performance?

Maintaining your wheel and bearing performance is crucial for vehicle safety and efficiency. Wheel and bearing issues can lead to costly repairs and unsafe driving conditions. Regular maintenance is essential to prevent potential failures. This guide will provide actionable tips to help you keep your wheels and bearings in top condition.

Take a moment to reflect on the last time you checked your wheel and bearing system. Many drivers overlook this aspect of vehicle care. Proper lubrication and regular inspections are key. Without them, small problems can escalate into more significant challenges. A little attention goes a long way.

As you read on, consider how often you monitor your wheel and bearing performance. Are you diligent in your inspections, or do you risk overlooking signs of wear? This advice is not just about longevity; it’s about ensuring a safe driving experience on the road.

Understanding Wheel and Bearing Performance: An Overview

Understanding wheel and bearing performance is vital for any vehicle's efficiency. Wheels provide the foundation for movement and stability. Bearings reduce friction, allowing smooth rotation. This system impacts fuel efficiency and overall safety.

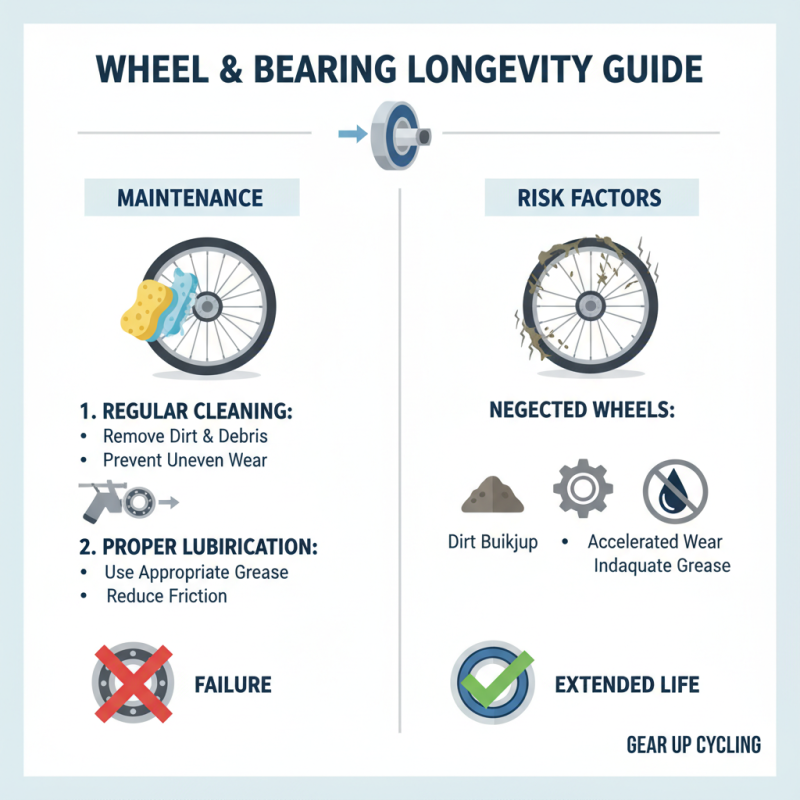

Improper maintenance can lead to uneven wear. This could cause vibrations or noise during operation. Regular checks should include inspecting for dirt or damage. Cleaning bearings and applying appropriate lubricants can improve their lifespan significantly. If they appear worn, replacing them prevents potential failure.

Drivers often overlook this part. Ignoring these components can lead to costly repairs. Pay attention to unusual sounds. They are often the first sign of trouble. Regular inspections and timely repairs ensure both wheels and bearings perform at their best.

Common Factors Affecting Wheel and Bearing Longevity

When it comes to wheel and bearing longevity, several factors play a critical role. One major issue is regular maintenance. Neglected wheels can accumulate dirt and debris. This buildup can cause uneven wear and tear. It's vital to clean wheels regularly. Pay attention to lubrication as well. Use the appropriate grease for bearings. Inadequate lubrication leads to friction, which can wear them down quickly.

Environmental factors also significantly affect performance. Moisture and dirt can infiltrate bearings, leading to corrosion. Use protective covers when possible. Additionally, extreme temperatures may degrade the materials. Examine your wheels' physical condition routinely. Look for cracks or deformities. These signs often indicate deeper problems.

Improper installation can further compromise longevity. It’s easy to overlook small details. Tightening bolts too much can warp bearings; leaving them loose can lead to failure. Familiarize yourself with correct installation techniques. A small mistake can lead to costly repairs down the line. It’s essential to act proactively and evaluate your wheel and bearing condition frequently.

Regular Maintenance Practices to Enhance Performance

Maintaining wheel and bearing performance is crucial for vehicle safety and efficiency. Regular maintenance can prevent costly repairs and enhance performance. According to industry reports, proper upkeep can extend the lifespan of components by up to 50%. This highlights the importance of adopting effective maintenance practices.

One essential tip is to inspect wheel bearings routinely. Look for signs of wear, such as unusual noises or vibrations. These may indicate that bearings are nearing failure. Frequent checks can help catch issues early. Additionally, cleaning the bearings and applying lubricant can enhance their functionality. Aim to perform these tasks every 6,000 miles or as specified in your vehicle's manual.

Another critical aspect is tire maintenance. Ensure tires are inflated to the recommended pressure. Under-inflated tires can lead to uneven wear and stress on bearings. Conduct visual inspections for cuts or damage. Additionally, rotating tires every 5,000 to 7,500 miles helps distribute wear evenly. This proactive approach can prevent problems down the line. Remember, neglect can lead to unpredictable failures. Engage in regular practices to safeguard your vehicle's performance.

Key Indicators of Wear: When to Replace Wheels and Bearings

Wheels and bearings play a crucial role in smooth operation. Regular wear can significantly affect performance. Look for key indicators of wear to determine when to replace these components.

Listen for unusual noises. Squeaks or grinding sounds often signal that bearings are worn out. If your wheels wobble or feel loose, it's time to inspect them closely. Visual checks are essential. Look for cracks or flat spots on the wheels. These are signs that they are beyond their service life.

To maintain optimal performance, regularly clean your wheels and bearings. Clear debris that can cause additional wear. Lubrication is vital; ensure that bearings are well-greased. Avoid overloading your equipment, as this can accelerate wear. Keep an eye on wear patterns and don't ignore small issues. Address them before they become bigger problems. Regular maintenance can save you time and money.

Top Tips for Maintaining Your Wheel and Bearing Performance

This chart illustrates the performance levels of wheels and bearings at different stages of wear, highlighting the importance of timely inspections and replacements to maintain optimal functionality.

Cost-Benefit Analysis of Upkeep versus Replacement in the Long Run

Maintaining wheel and bearing performance is crucial for vehicle safety. Regular upkeep includes checking for wear, applying lubrication, and monitoring alignment. These practices help prevent costly failures. Ignoring maintenance can lead to unexpected breakdowns. In contrast, replacing worn components can be a simpler, albeit more expensive, solution.

A cost-benefit analysis reveals interesting insights. Regular maintenance often costs less over time than a full replacement. However, the upfront costs of upkeep can be daunting for some. Missing a routine check means facing larger expenses later. It’s tempting to overlook small issues, but those can snowball. In many cases, investing in upkeep pays off better than a sudden replacement.

The decision to maintain or replace hinges on several factors. Age and usage of the vehicle affect this. For instance, older vehicles may need more frequent checks. On the other hand, newer models might allow for longer intervals. Ultimately, each owner should consider their budget and tolerance for risk. A proactive approach often results in better long-term savings. Ignoring minor issues can lead to regret.

Top Tips for Maintaining Your Wheel and Bearing Performance

| Maintenance Tip | Frequency | Cost (USD) | Estimated Lifespan (Months) | Cost-Benefit Score |

|---|---|---|---|---|

| Regular Cleaning | Monthly | 10 | 12 | 10 |

| Lubrication | Quarterly | 15 | 24 | 20 |

| Inspection for Wear | Bi-Annually | 25 | 6 | 15 |

| Replacement of Damaged Parts | As Needed | 100 | 36 | 5 |

| Professional Overhaul | Yearly | 200 | 60 | 8 |

Related Posts

-

Top 10 Side Wheel Bearing Signs of Wear and Replacement Tips

-

How to Replace Front Hub Bearing in Your Vehicle in 2025

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

What is a Front Axle Bearing and How to Choose the Right One

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure