What Are Tiny Ball Bearings and Their Uses?

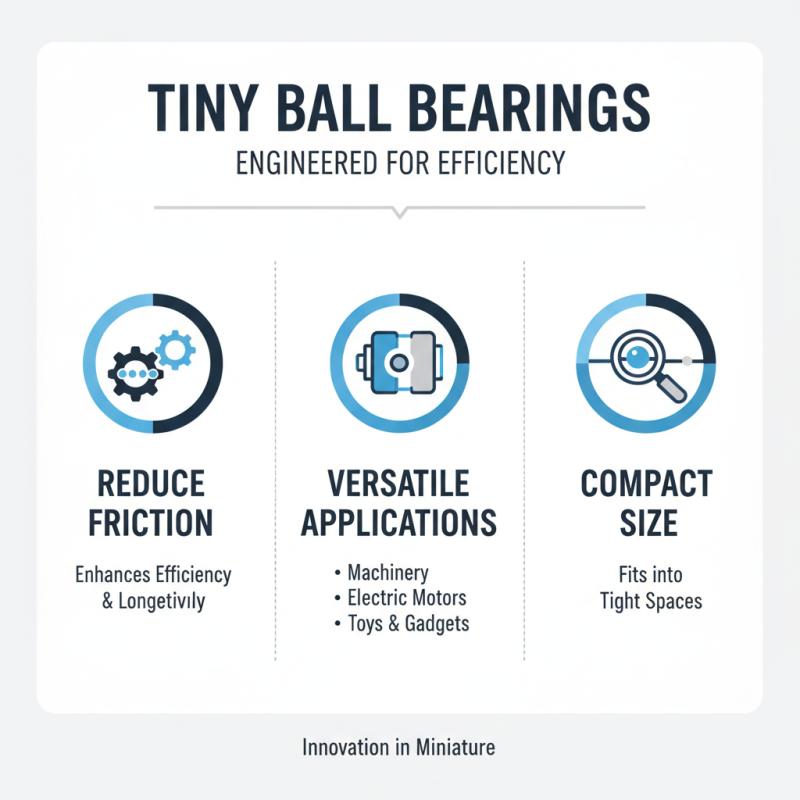

Tiny Ball Bearings play a crucial role in various mechanical applications. These small precision components help reduce friction and support smooth movement in diverse devices. From skateboards to electric motors, their significance is immense.

Manufactured with utmost precision, tiny ball bearings come in different sizes and materials. Their compact nature allows them to fit into tight spaces. This versatility is often underappreciated, yet it is essential for engineering efficiency. The world often overlooks their importance, focusing instead on larger components.

Notably, tiny ball bearings enhance performance in many sectors. Their applications range from consumer electronics to aerospace. However, this raises questions about their longevity and reliability. Are smaller bearings truly dependable? The design and maintenance of these bearings can be challenging. More awareness could lead to improvements in quality. Understanding tiny ball bearings is vital for engineers and consumers alike.

What Are Tiny Ball Bearings?

Tiny ball bearings are small, spherical components that reduce friction in mechanical systems. Their primary function is to allow smooth movement between parts while minimizing wear. This design is crucial in industries such as automotive and aerospace. According to a recent report by MarketsandMarkets, the global ball bearing market is expected to reach $26.6 billion by 2025, demonstrating their significant role in modern machinery.

These tiny components come in various sizes and materials. Steel and ceramic are common choices, each offering distinct advantages. Steel bearings are durable and economical. Ceramic bearings are lighter and exhibit better corrosion resistance. However, the production process can lead to inconsistencies. The precision required in manufacturing affects the performance. A small defect can lead to a malfunction, highlighting the importance of quality control in production.

Tiny ball bearings are prevalent in everyday devices. From computer hard drives to skateboards, they enable seamless functionality. However, not all applications benefit equally from their use. In some cases, they may fail under extreme conditions or heavy loads. Understanding the limitations of these components is vital for engineers and designers. Proper analysis ensures that the right type of bearing is selected for each specific application.

What Are Tiny Ball Bearings and Their Uses?

| Dimension (mm) | Material | Load Capacity (N) | Operating Temperature (°C) | Common Applications |

|---|---|---|---|---|

| 1.5 | Stainless Steel | 10 | -20 to 80 | Toys, Small Electronics |

| 3.0 | Chrome Steel | 50 | -20 to 120 | Cameras, Robotics |

| 4.0 | Ceramic | 75 | -40 to 150 | Medical Devices, High-speed Tools |

| 5.0 | Plastic | 15 | -20 to 60 | Appliances, Fan Motors |

The Composition and Design of Tiny Ball Bearings

Tiny ball bearings are crucial components in many machines and devices. Their design and composition greatly affect their performance. Made from materials like steel or ceramic, these bearings provide smooth rotation and minimize friction. The precision of their size ensures they fit seamlessly into various applications, from small electronics to larger industrial machinery.

The design of tiny ball bearings involves intricate engineering. The balls are arranged in a raceway, allowing for efficient load distribution. Their spherical shape enables them to handle both radial and axial loads effectively. This versatility is vital in applications such as automotive engines and household appliances. However, not all designs achieve optimal performance. Sometimes, misalignment occurs, leading to uneven wear and reduced efficiency.

The manufacturing process also plays a role in their effectiveness. High-quality control standards are essential. Yet, even with strict guidelines, variations can impact the end product. Some bearings may not fit perfectly, leading to operational challenges. These imperfections remind us that continuous improvement is necessary in the world of engineering. Addressing these issues can lead to innovations in design and material usage.

Common Applications of Tiny Ball Bearings

Tiny ball bearings are crucial components in many devices. They are small, spherical objects that reduce friction in rotating parts. Their primary purpose is to support weight and facilitate smooth movement. You’ll find them in everyday items, such as toys, electronics, and machinery.

In the world of robotics, tiny ball bearings allow precise movements. They are often used in joints and wheels, providing stability and ease of operation. In household appliances, these bearings can be found in blenders and motors. They enhance performance and extend the lifespan of these devices.

Tips: When selecting tiny ball bearings, consider the load capacity and material. Choose the right type for your device. Remember that not all applications require the same specifications. Rethink your choices if a bearing wears out quickly. Sometimes, a better fit can make all the difference.

You can find tiny ball bearings in bicycles too. They improve the efficiency of pedals and wheels. A well-maintained bearing can enhance your ride significantly. However, neglecting their upkeep may lead to issues. Keep these components clean and lubricated for optimal performance.

Advantages of Using Tiny Ball Bearings

Tiny ball bearings play a crucial role in many applications. These small components reduce friction between moving parts, enhancing overall efficiency. They are widely used in machinery, electric motors, and even toys. Their compact size allows them to fit into tight spaces where larger bearings cannot.

One significant advantage of tiny ball bearings is their ability to improve performance. By minimizing friction, machines run smoother and last longer. This means less wear and tear. Furthermore, they contribute to energy savings. A motor with ball bearings uses less energy than one without. This can lead to cost savings over time.

**Tip:** When selecting ball bearings, consider the material. Steel is common, but ceramic options can offer added durability.

Another benefit is their versatility. Tiny ball bearings can be used in various sectors, including automotive, aerospace, and household appliances. They help create efficient designs while minimizing noise and vibration. However, it’s essential to understand their limitations too. They may not always handle heavy loads or extreme temperatures effectively.

**Tip:** Regular inspection and maintenance can extend the life of your ball bearings. Clean them periodically to prevent dirt buildup.

Maintenance Tips for Small Ball Bearings

Tiny ball bearings are crucial components in many machines and devices. Their small size allows them to fit in tight spaces. However, even small components need proper maintenance to function efficiently.

Regular cleaning is essential for tiny ball bearings. Dust and debris can hinder their performance. Use a soft cloth or a brush to remove dirt. Inspect them frequently for any signs of wear. If you notice any irregularities, it’s a good idea to replace them.

Lubrication is another key aspect of maintenance. Proper lubrication reduces friction and heat. A thin layer of oil or grease works well. However, applying too much can attract more dust, which is counterproductive. Balance is necessary. Lastly, ensure they are properly installed to maximize performance. Misalignment can lead to premature failure.

Attention to these details can extend the life of tiny ball bearings significantly.

Related Posts

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

How to Choose the Right Cushion Bearing for Your Project Needs

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

What is Rv Wheel Bearings and How to Choose the Right Ones for Your Vehicle

-

Top Tips for Choosing the Right Brake Bearings for Your Vehicle