Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

A bad wheel bearing can lead to a myriad of problems for your vehicle, from decreased performance to serious safety hazards. As drivers become more aware of how crucial this component is to their vehicle’s functionality, recognizing the signs of a bad wheel bearing becomes essential. In 2025, understanding these signs can not only save you from costly repairs but also enhance your road safety.

Typically, a bad wheel bearing will manifest through various symptoms, including unusual noises, vibrations, or uneven tire wear. By knowing what to look for, you can address these issues before they escalate into more significant problems. In this guide, we will explore the top signs that indicate a bad wheel bearing and provide practical solutions for addressing them. Whether you are a seasoned mechanic or a casual driver, being informed about the health of your wheel bearings is vital for maintaining your vehicle’s overall performance and safety on the road.

Common Symptoms Indicating a Failing Wheel Bearing

One of the most critical aspects of vehicle maintenance is monitoring the condition of wheel bearings. Failing wheel bearings can lead to unsafe driving conditions and costly repairs. Common symptoms of a failing wheel bearing include unusual noises, such as grinding or humming sounds, which may become louder when cornering. Additionally, you might notice a vibration in the steering wheel or vehicle body, indicating that the bearings are not functioning correctly. Another sign is uneven tire wear, which can signal that the wheel alignment is off, often due to bearing issues.

To ensure your safety and prolong the life of your vehicle, it's essential to address these symptoms promptly. If you suspect a failing wheel bearing, consider performing a visual inspection of the wheels. Look for any signs of grease leaking from the bearing seals or listen for noises while spinning the wheel by hand. It’s a good practice to have your wheel bearings checked during routine maintenance.

Tips: If you're not comfortable inspecting wheel bearings yourself, it’s wise to consult a professional mechanic. Additionally, regularly rotating your tires can help distribute wear evenly, potentially extending the lifespan of your wheel bearings. Always respond to unusual vehicle sounds immediately to avoid further damage.

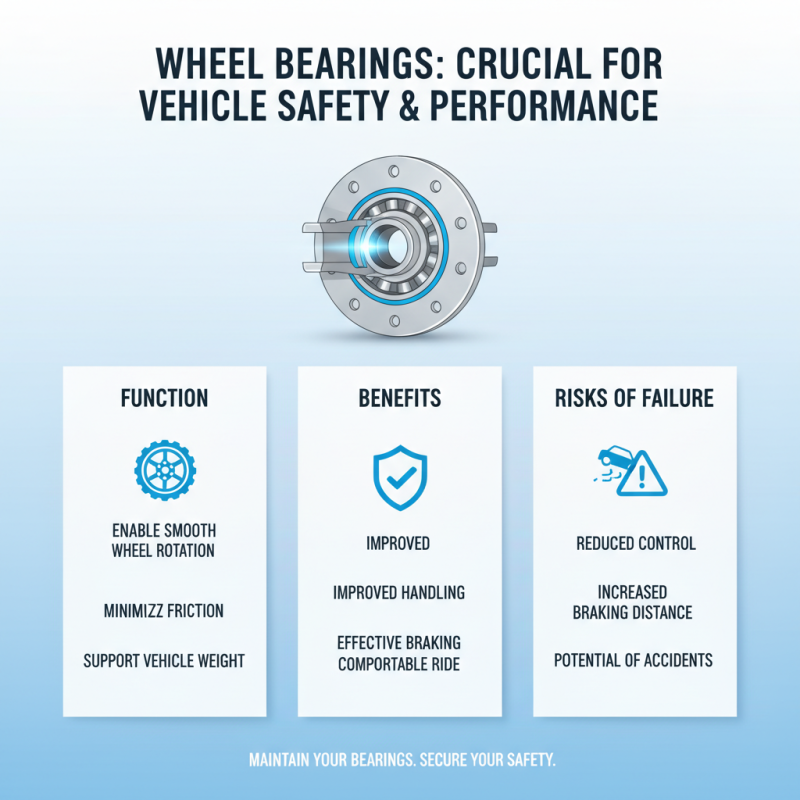

How Wheel Bearings Function and Their Importance in Vehicle Safety

Wheel bearings play a crucial role in the safety and performance of a vehicle. They allow the wheels to spin with minimal friction, ensuring a smooth ride while supporting the weight of the vehicle. When functioning properly, wheel bearings contribute to effective braking and handling, which are essential for driver and passenger safety. If wheel bearings wear out or fail, they can lead to serious consequences, including reduced control over the vehicle and increased braking distance.

To maintain the integrity of your wheel bearings, regular inspections are essential. Check for any signs of unusual noise, such as grinding or humming sounds, which may indicate that a bearing is failing. Additionally, if you feel vibrations in the steering wheel or notice uneven tire wear, it’s important to have the wheel bearings examined by a professional.

Tips: Keeping your vehicle well-maintained can prevent wheel bearing issues. Regularly check and change your vehicle's lubricant to help reduce friction and wear on the bearings. Paying attention to any changes in driving behavior or vehicle performance can also alert you to potential wheel bearing problems before they escalate. If you suspect a problem, don’t delay in seeking a diagnosis to ensure your vehicle remains safe and reliable on the road.

Step-by-Step Guide to Diagnosing Wheel Bearing Issues

Diagnosing wheel bearing issues requires a systematic approach to ensure vehicle safety and performance. The first step is to conduct a visual inspection of the wheel assembly. Look for signs of wear, rust, or damage around the wheel hub and bearing area. According to a report by the National Highway Traffic Safety Administration (NHTSA), over 20% of vehicle accidents are linked to problems with wheel components, making early detection vital.

Next, perform a test drive to listen for abnormal sounds. A worn wheel bearing often produces a low rumbling or grinding noise that intensifies with speed or when turning. This auditory cue can be a significant indicator of impending failure. Industry data from the Automotive Service Association indicates that replacing a faulty wheel bearing can prevent more serious issues, such as brake failure or wheel detachment, which could lead to catastrophic accidents.

Finally, utilize specialized tools such as a dial indicator to measure any play in the bearing. If excessive movement is detected, it’s a strong indication that the bearing needs replacement. Regular maintenance checks and prompt diagnosis can extend the lifespan of your vehicle and enhance safety on the road, reinforcing the importance of being proactive about wheel bearing health.

Top Signs of a Bad Wheel Bearing

Effective Methods for Repairing or Replacing Bad Wheel Bearings

When dealing with bad wheel bearings, it’s essential to understand the effective methods for repair or replacement to ensure vehicle safety and performance. One of the first steps in addressing the issue is to accurately diagnose the problem. Listen for distinctive noises such as grinding or humming while driving, which often indicate that your wheel bearings may be failing. Once diagnosed, you can proceed with repair or replacement.

For repairs, if the wheel bearing is showing minor signs of wear, you might be able to apply lubrication to extend its life temporarily. However, this is a short-term fix and shouldn’t substitute a complete replacement. For serious issues, replacing the wheel bearing is the safest option. This involves safely lifting the vehicle, removing the wheel, and extracting the hub assembly to access the bearing.

Make sure to clean the area thoroughly before installation. Use appropriate tools and follow the manufacturer's guidelines for torque specifications to ensure the new bearing is properly secured. Always consider consulting a professional mechanic if you’re unsure, as they can provide valuable expertise in handling complex wheel bearing issues.

Preventive Maintenance Tips to Extend Wheel Bearing Life

To extend the life of your wheel bearings and prevent costly repairs in 2025, implementing effective preventive maintenance practices is essential. Regularly inspecting your vehicle can help identify signs of wear and tear early on. Start by checking the wheel bearings for any unusual noises such as grinding or humming, especially when turning corners. Observing any visible damage or play in the wheel can also indicate a failing bearing. Performing these checks periodically ensures that any issues are addressed before they escalate.

Another key aspect of preventive maintenance is ensuring proper lubrication of the wheel bearings. This involves using high-quality grease and following manufacturer guidelines for maintenance intervals. Keeping bearings well-lubricated reduces friction and heat buildup, prolonging their lifespan. Additionally, regular wheel alignment and tire rotation help distribute weight evenly, which can prevent undue stress on the wheel bearings. Paying attention to your driving habits, such as avoiding potholes and rough terrain, can also significantly impact the health of your wheel bearings.

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

| Sign | Description | Prevention Tips |

|---|---|---|

| Unusual Noises | Grinding, growling, or humming sounds while driving. | Regularly inspect and listen for sounds during test drives. |

| Vibration | Excessive shaking in the steering wheel or vehicle. | Rotate tires regularly to ensure even wear. |

| Wheel Play | Detectable movement when the wheel is rocked back and forth. | Keep wheel bearings properly lubricated and adjusted. |

| Uneven Tire Wear | Tires may wear inconsistently due to a bad bearing. | Conduct regular alignment checks and rotate tires. |

| ABS Warning Light | The ABS light may come on if a wheel bearing is failing. | Monitor dashboard alerts and perform routine checks. |

Related Posts

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

Top Tips for Choosing the Right Brake Bearings for Your Vehicle