Top 10 Side Wheel Bearing Signs of Wear and Replacement Tips

The side wheel bearing is a crucial component in the automotive industry, playing a significant role in ensuring the smooth operation of vehicle wheels. According to the National Highway Traffic Safety Administration (NHTSA), wheel bearing failure is a contributing factor in approximately 10% of all vehicle-related accidents. As vehicles age and accumulate mileage, the side wheel bearing is subject to wear and tear, resulting in potential problems that can affect vehicle safety and performance.

Understanding the signs of wear in side wheel bearings is essential for maintaining vehicle integrity. Common symptoms include unusual noises during turning, vibrations in the steering wheel, and uneven tire wear. A report from the Institute of Mechanical Engineers indicates that proactive monitoring of wheel bearings can reduce the chances of catastrophic failure by up to 45%. Identifying these signs early not only enhances safety but can also save vehicle owners from costly repairs down the line. Therefore, being attentive to the condition of side wheel bearings and knowing when to seek replacement is vital for any responsible vehicle owner.

Understanding Side Wheel Bearings and Their Importance

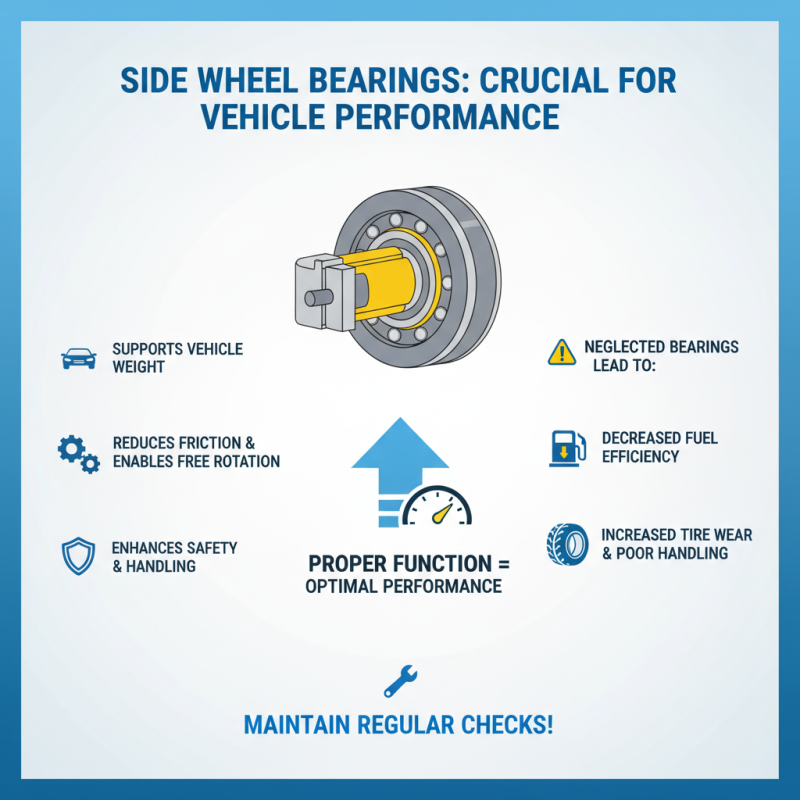

Side wheel bearings play a crucial role in ensuring the smooth operation of a vehicle's wheel system. These components are designed to support the weight of the vehicle, reduce friction, and enable the wheels to rotate freely. By maintaining proper alignment and minimizing wear between moving parts, side wheel bearings help to enhance overall vehicle performance and safety. Neglecting these bearings can lead to significant issues, such as decreased fuel efficiency, increased tire wear, and compromised handling, making it essential for drivers to understand their importance.

Regular inspection of side wheel bearings is vital for early detection of wear and potential failure. Signs of worn bearings may include unusual noises, such as grinding or humming, as well as vibrations felt through the steering wheel or floorboards. Additionally, uneven tire wear can indicate an issue with the bearings. By recognizing these symptoms early, vehicle owners can take proactive measures, such as lubrication or replacement, to avoid costly repairs and maintain optimal vehicle performance. Regular maintenance is not just about extending the life of side wheel bearings; it also contributes to the overall safety of the vehicle, providing peace of mind for drivers and passengers alike.

Common Signs of Wear in Side Wheel Bearings

Side wheel bearings play a crucial role in the smooth operation of your vehicle, and recognizing the signs of wear can prevent costly repairs down the road. One of the primary signs that your side wheel bearings may be failing is a noticeable grinding or humming noise that increases with speed. This sound often indicates that the bearing is worn or damaged, allowing metal components to make contact in ways they shouldn't. Additionally, if you experience vibrations in the steering wheel or the vehicle itself, this can signal that the bearings are not functioning properly and may need immediate attention.

Another common sign of wear is excessive play in the wheel itself. If you notice that there is a significant amount of lateral movement when you attempt to wiggle the wheel, this could indicate that the bearing is deteriorating. Furthermore, if you observe uneven tire wear, it may point to issues with the wheel bearings, as misalignment can occur when the bearings are compromised. Regular checks of these symptoms can help vehicle owners stay ahead of potential issues, ensuring that replacement occurs before further damage occurs.

Top 10 Side Wheel Bearing Signs of Wear and Replacement Tips - Common Signs of Wear in Side Wheel Bearings

| Sign of Wear | Description | Replacement Tips |

|---|---|---|

| Unusual Noises | Grinding or rumbling sounds when driving. | Immediately inspect bearings; replace if the sound persists. |

| Vibration | Feeling vibrations through the steering wheel or body of the vehicle. | Check for imbalance; consider aligning or replacing wheel bearings. |

| Looseness | Wobbling of the wheel while driving. | Tighten or replace bearings if excessive play is noticed. |

| Heat Generation | High temperatures around the wheel hub during operation. | Inspect for lubrication issues and replace bearings when overheating. |

| Grease Leakage | Visible grease around the wheel hub indicates failure. | Replace bearings immediately if grease leakage is found. |

| Steering Issues | Difficulty steering or feeling like the vehicle is drifting. | Have wheel bearings inspected and replaced to restore balance. |

| Tire Wear | Uneven or rapid tire wear can indicate bearing issues. | Check bearings when unusual tire wear is detected and replace as required. |

| ABS Malfunction | Activation of ABS warning light due to bearing failure. | Inspect bearings and address ABS warnings promptly by replacing faulty parts. |

| Corrosion | Rust or corrosion on the bearing surface. | Replace bearings showing signs of corrosion to prevent further damage. |

| Squeaking Sounds | Squeaks or squeals when turning the wheel. | Inspect and consider replacement if sounds persist during operation. |

Consequences of Ignoring Worn Side Wheel Bearings

Ignoring worn side wheel bearings can lead to serious consequences that affect both the vehicle's performance and safety. Wear and tear on these bearings can cause tire misalignment, leading to uneven tire wear and compromising steering responsiveness. Moreover, neglected bearings can result in excessive play in the wheel, causing dangerous handling issues and increasing the likelihood of accidents.

To avoid these issues, it's essential to watch for signs of wear such as unusual noises coming from the wheel area, vibrations while driving, or an unsteady feel when steering. If any of these symptoms arise, it’s advisable to seek professional inspection.

In addition, regular maintenance and timely replacement can significantly prevent more severe problems down the line. Keep an eye on the mileage since the last bearing replacement and adhere to recommended service intervals. Performing routine checks on the wheel bearings during tire rotations can also help identify potential wear early, ensuring safety and prolonging the life of your vehicle.

Top 10 Signs of Worn Side Wheel Bearings

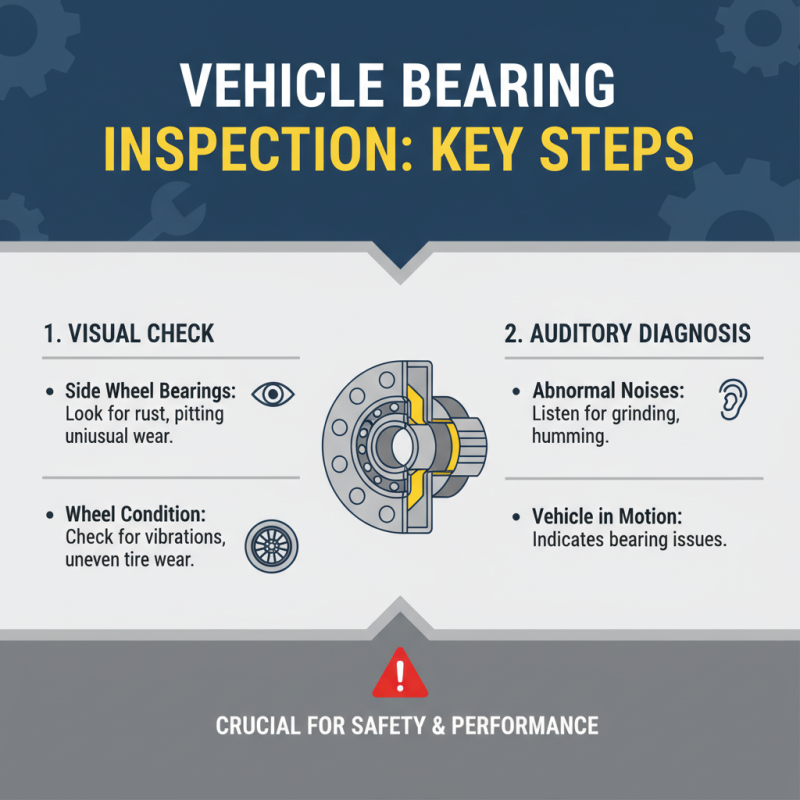

Steps for Inspecting and Diagnosing Bearing Wear

When it comes to maintaining your vehicle, inspecting and diagnosing bearing wear is crucial for ensuring both safety and performance. The first step in this process involves visual inspection. Begin by examining the side wheel bearings for any visible signs of damage, such as rust, pitting, or unusual wear on the surfaces. Additionally, listen for any abnormal noises such as grinding or humming while the vehicle is in motion, which can indicate bearing issues. Pay attention to the condition of the wheel itself, as vibrations or uneven wear patterns can also signal problems with the bearings.

Next, utilize specific diagnostic techniques to assess bearing performance. A 'wiggle test', where you shake the wheel back and forth while the vehicle is lifted, can reveal looseness in the bearings that may not be visible to the naked eye. Additionally, consider performing a rotational test by spinning the wheel; smooth rotation without resistance is a sign of healthy bearings, while a rough or stiff feel suggests wear. Remember to check the grease condition; degraded grease can lead to increased friction and eventual bearing failure. Regular inspections and timely diagnosis of any wear signs can prolong the life of your bearings and enhance your vehicle's overall function.

Replacement Tips for Side Wheel Bearings and Maintenance Practices

When it comes to maintaining the integrity of your vehicle, paying attention to side wheel bearings is crucial. These components are vital for the smooth operation of your wheels, and their wear can significantly affect vehicle performance and safety. Regular inspections can identify signs of wear early, such as unusual noises during driving, vibrations, or uneven tire wear. According to a report from the Institute of Automotive Engineers, approximately 35% of vehicle issues stem from neglected bearing maintenance. Ensuring that bearings are checked during routine services can prevent costly repairs down the line and enhance overall vehicle longevity.

Implementing best practices for bearing maintenance can greatly extend their lifespan. It is recommended to lubricate the bearings with high-quality grease at specific intervals, as per manufacturer guidelines, to prevent premature wear. Maintaining proper wheel alignment and tire pressure is also essential, as improper settings can place undue stress on wheel bearings. A study by the Society of Automotive Engineers indicates that adhering to preventive maintenance schedules can reduce the risk of bearing failure by up to 50%. By prioritizing these replacement tips and maintenance practices, drivers can ensure safer driving experiences and optimal vehicle performance.

Related Posts

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

Why Rotor Bearings Are Essential for Optimal Machine Performance

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying