Why Rotor Bearings Are Essential for Optimal Machine Performance

In the world of machine performance, the significance of rotor bearings cannot be overstated. Renowned industry expert Dr. Emily R. Stephens, a leading figure in mechanical engineering, once noted, "The efficiency of machinery fundamentally hinges on the reliability and precision of rotor bearings." This statement encapsulates the critical role that rotor bearings play in ensuring the seamless operation of various mechanical systems, from turbines to electric motors.

Rotor bearings not only mitigate friction and support rotating components, but they also enhance the overall durability and reliability of machines. Their design and material composition are pivotal in determining performance metrics, which can greatly influence productivity and operational costs. As machines become more complex and operate under increasingly demanding conditions, understanding the function and importance of rotor bearings has never been more vital for engineers and manufacturers alike.

As we delve deeper into the mechanisms of rotor bearings, it becomes clear that they are essential for achieving optimal machine performance. They serve as the backbone of numerous industrial applications, facilitating smooth motion and reducing wear and tear. This exploration will highlight the intricacies of rotor bearings and their indispensable contributions to mechanical systems, reinforcing why they are an integral element in the pursuit of efficiency and effectiveness in machine operations.

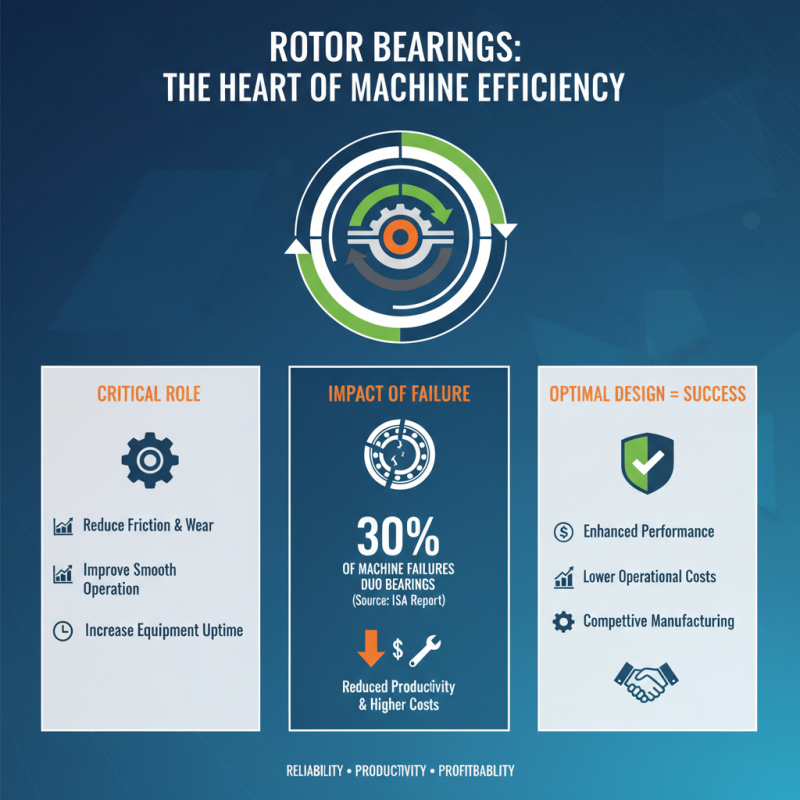

Role of Rotor Bearings in Machine Efficiency

Rotor bearings play a pivotal role in the efficiency and performance of machines across various industries. According to a report by the International Society of Automation, nearly 30% of machine failures are attributed to bearing-related issues, underscoring the importance of high-quality rotor bearings in maintaining equipment uptime. When bearings are optimally designed and maintained, they significantly reduce friction and wear, enabling machines to operate smoothly and efficiently. This translates into improved productivity and reduced operational costs, which are crucial for any competitive manufacturing environment.

To enhance machine efficiency, selecting the right type of rotor bearing is critical. For instances where high-speed operation is required, such as in turbines or electric motors, using advanced materials and robust designs can lead to efficiencies exceeding 90%. Furthermore, adopting predictive maintenance strategies, which utilize data analytics to monitor bearing performance, can help identify potential failures before they occur. This proactive approach minimizes downtime and maximizes productivity, aligning with findings from the Bearing Manufacturers Association that suggest proper maintenance can extend bearing lifespan by as much as 40%.

Tips:

- Regularly check and maintain lubrication levels to ensure bearings operate smoothly and efficiently.

- Monitor temperature and vibration levels to detect any anomalies that could signal bearing wear or failure.

- Invest in training for maintenance personnel to recognize early signs of bearing issues, which can save time and reduce costs in the long run.

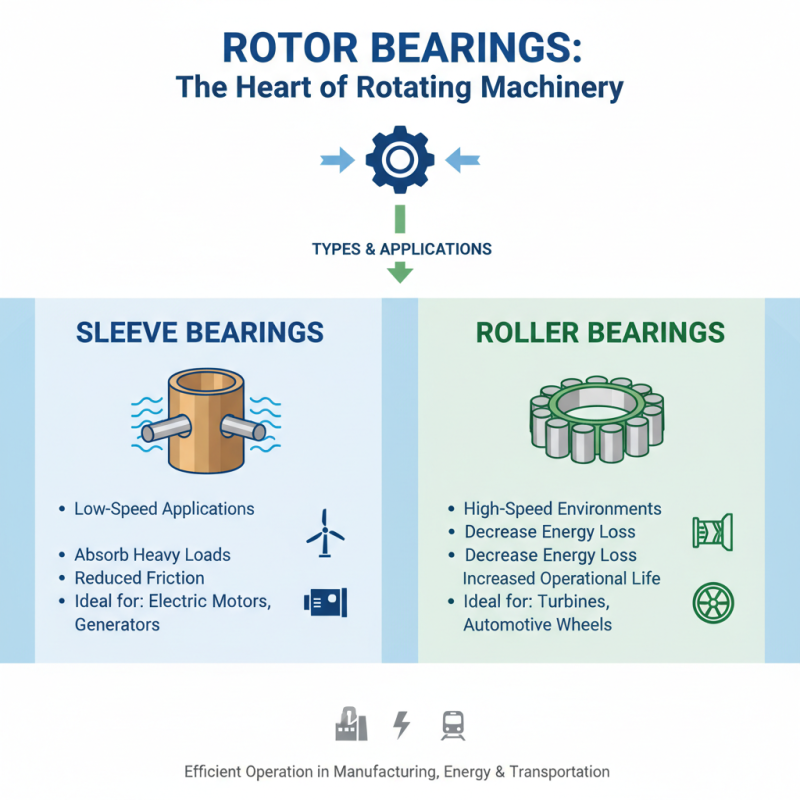

Types of Rotor Bearings and Their Applications

Rotor bearings play a crucial role in the efficient operation of various machines, particularly in the fields of manufacturing, energy, and transportation. There are several types of rotor bearings, each serving specific applications based on load capacity, speed requirements, and environmental conditions. For instance, **sleeve bearings** are often used in low-speed applications due to their ability to absorb heavy loads and reduce friction, making them ideal for electric motors and generators. On the other hand, **roller bearings**, which utilize rolling elements, are preferred in high-speed environments as they decrease energy loss and increase operational life.

In addition, **magnetic bearings** have emerged as a significant innovation, providing contactless support that can drastically reduce wear and maintenance costs. They operate efficiently in environments prone to contamination, such as those found in chemical processing or food production industries. According to a report by the International Journal of Machine Tools and Manufacture, the use of roller and magnetic bearings in high-speed machinery can enhance performance by up to 30% compared to traditional bearing types. This efficiency gain can lead to substantial reductions in energy consumption, which is critical for industries aiming for lower operational costs and greater sustainability.

Each type of rotor bearing not only caters to specific application needs but also contributes significantly to overall machine reliability and performance. As industries continue to evolve towards more advanced technologies, the importance of selecting the appropriate rotor bearing for each application becomes increasingly vital in achieving optimal machine performance.

Factors Affecting the Performance of Rotor Bearings

Rotor bearings play a critical role in the performance of various machinery, acting as crucial components that support and enable the smooth rotation of the shaft. Several factors greatly influence the efficiency and durability of rotor bearings. One major factor is the type of lubrication used; proper lubrication reduces friction and wear, extending the life of the bearings significantly. Additionally, environmental conditions such as temperature and humidity can impact the performance of rotor bearings, as extreme conditions may lead to overheating or corrosion if the bearings are not designed to withstand them.

Another important factor is load capacity. Bearings must be selected based on the load they will bear during operation. Overloading can lead to premature failure, while underloading may not utilize the bearing's potential fully. Vibration and alignment are also key considerations; misalignment can cause uneven wear and decrease the bearing's efficiency.

Tips: Regular maintenance is essential to ensure optimal performance of rotor bearings. Implementing a routine inspection schedule can help identify early signs of wear and tear, allowing for timely interventions. Furthermore, utilizing the correct installation procedures is vital; improper installation can lead to alignment issues and adversely affect bearing performance.

Maintenance Practices for Rotor Bearings

Rotor bearings play a crucial role in the performance and longevity of machinery across various industries. Regular maintenance practices are vital to ensure that these bearings operate efficiently. According to a study by the American Society of Mechanical Engineers (ASME), approximately 30% of all machine failures can be attributed to bearing issues. This statistic emphasizes the importance of routine inspections and proactive maintenance strategies, which can significantly reduce unplanned downtime and extend the lifespan of rotor bearings.

Effective maintenance practices for rotor bearings include lubrication, alignment checks, and vibration analysis. Proper lubrication is essential, as it minimizes friction and wear, prolonging bearing life. The International Organization for Standardization (ISO) recommends that machinery should undergo lubrication based on operational parameters rather than a fixed schedule, allowing for adjustments according to actual conditions. Moreover, employing vibration analysis techniques can help detect early signs of bearing wear or misalignment, allowing for timely interventions. In fact, the Maintenance Institute reports that predictive maintenance techniques can lead to a reduction in unexpected failures by as much as 70%, highlighting the efficiencies gained through diligent maintenance efforts.

Why Rotor Bearings Are Essential for Optimal Machine Performance - Maintenance Practices for Rotor Bearings

| Dimension | Importance | Maintenance Practice | Frequency | Expected Lifespan |

|---|---|---|---|---|

| Load Capacity | Ensures machines can handle operational loads without failure | Regular inspection for signs of wear | Monthly | 5-10 years |

| Alignment | Prevents uneven wear and overheating | Check and adjust alignment regularly | Quarterly | 5-15 years |

| Lubrication | Reduces friction and heat generation | Maintain proper lubricant levels and quality | Weekly | 3-10 years |

| Temperature Monitoring | Detects overheating issues early | Use thermal imaging or sensors for monitoring | Monthly | 5-10 years |

| Vibration Analysis | Identifies imbalance and misalignment | Conduct vibration tests regularly | Annually | 5-10 years |

Impact of Rotor Bearings on Overall Machine Lifespan

Rotor bearings play a crucial role in ensuring the optimal performance and longevity of industrial machinery. According to a report by the International Journal of Quality Engineering and Technology, approximately 30% of machine maintenance costs stem from issues related to bearing failures. This highlights the significant impact rotor bearings have not only on operational efficiency but also on the overall lifespan of a machine. When rotor bearings are properly maintained and functioning correctly, they can significantly reduce friction and wear, leading to fewer breakdowns and extended service life.

Furthermore, a study by the American Society of Mechanical Engineers (ASME) indicates that machines with high-quality bearings can achieve a lifespan increase of up to 50% compared to those with inferior alternatives. This statistic underscores the importance of investing in robust rotor bearings for machinery. By minimizing vibrations and maintaining precise alignment, rotor bearings greatly enhance the performance of rotating equipment, thus translating into higher reliability and lower operational costs over time. Proper selection and maintenance of these components contribute to a machine's overall resilience, underscoring their essential role in industrial applications.

Related Posts

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

What is a Front Axle Bearing and How to Choose the Right One

-

Top Tips for Choosing the Right Brake Bearings for Your Vehicle