How to Replace Front Hub Bearing in Your Vehicle in 2025

In the ever-evolving automotive industry, understanding the intricacies of vehicle maintenance is crucial for both professionals and enthusiasts alike. One key component that plays a vital role in vehicle performance and safety is the Front Hub Bearing. According to a report from the Automotive Components Manufacturers Association, approximately 25% of all vehicle-related accidents are linked to component failures, with Front Hub Bearings being a significant contributor. Proper maintenance and timely replacement of these components can mitigate such risks, ensuring not only optimal performance but also the safety of all passengers.

Moreover, as noted by Dr. James McKenzie, a leading expert in automotive engineering, "The longevity and functionality of a Front Hub Bearing can directly influence the vehicle's handling and tire wear. Ignoring the signs of a failing bearing can lead to costly repairs and jeopardize driver safety." This statement underscores the importance of regular inspections and proactive maintenance as we look towards the improvements in hub bearing technology slated for 2025. As innovation progresses, understanding how to effectively replace Front Hub Bearings will become increasingly essential for vehicle owners, highlighting the need for comprehensive guidance in these practices.

Understanding Front Hub Bearings: Function and Importance in Vehicles

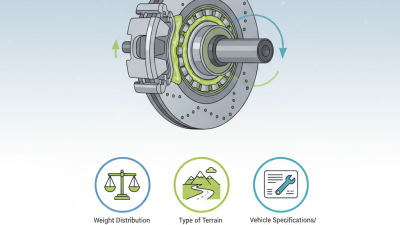

Front hub bearings play a crucial role in the overall functionality and safety of a vehicle. These components are situated within the wheel hub assembly, allowing the wheel to spin freely and smoothly while supporting the weight of the vehicle. Made up of precision-engineered steel balls or rollers housed within a race, front hub bearings help reduce friction between the wheel and the axle. This friction reduction is vital, as it contributes to fuel efficiency and overall performance while ensuring that the ride remains stable and controlled during operation.

In addition to their functional benefits, front hub bearings are integral to the vehicle's safety system. They help maintain proper wheel alignment and support the vehicle's braking system. When front hub bearings wear out or become damaged, it can lead to uneven tire wear, compromised handling, and increased stopping distances. This not only affects the driving experience but also poses significant risks on the road. Therefore, understanding the function and importance of front hub bearings is essential for vehicle owners to ensure timely maintenance and replacements, ultimately contributing to a safer and more reliable driving experience.

Identifying Symptoms of Worn Front Hub Bearings in 2025 Models

Identifying symptoms of worn front hub bearings in 2025 models is crucial for

maintaining vehicle safety and performance. As vehicles evolve, so do the bearing technologies and common wear indicators. In

2025, drivers should watch for noise characteristics such as grinding or humming sounds that increase with speed,

which often indicate bearing deterioration. According to a recent industry report, approximately 20%

of all vehicle maintenance issues are related to wheel components, highlighting the importance of addressing front hub bearing

wear swiftly.

Beyond auditory cues, visual inspections can reveal signs of wear. Look for uneven tire wear,

which can suggest that the bearings aren’t holding the wheel hub in alignment correctly. Additionally, if you experience

vibrations while driving or an unusual pulling sensation during turns, these could be symptoms of failing bearings. The

National Highway Traffic Safety Administration states that worn bearings can lead to

more severe issues like wheel separation, making early detection critical.

Tips: Regularly schedule vehicle maintenance checks to examine the front hub assemblies. Pay

attention to any changes in handling or noise, and address them promptly. For those who frequently drive in harsh conditions,

consider more frequent inspections to catch potential bearing issues before they escalate. Early intervention can save

both time and money.

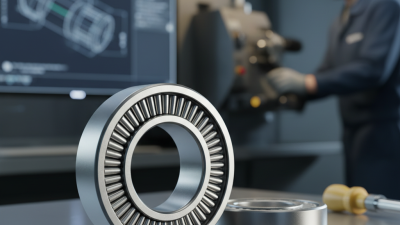

Essential Tools and Equipment for Replacing Hub Bearings Efficiently

When it comes to replacing front hub bearings in your vehicle, having the right tools and equipment at hand is crucial for an efficient and effective repair process. According to the National Institute for Automotive Service Excellence (ASE), proper tooling can reduce the time spent on such tasks by up to 30%. Essential tools include a high-quality hydraulic press, bearing pullers, and a torque wrench. These tools not only streamline the removal and installation process but also ensure that the bearings are seated correctly, which is vital for the longevity of the components.

In addition to basic hand tools like wrenches and sockets, specialized equipment such as a dial indicator can be particularly useful in measuring the runout of the hub assembly. This measurement is essential to identify any potential issues that could affect vehicle performance. The Automotive Service Association (ASA) highlights that improper installation of hub bearings can lead to premature failure, potentially costing the vehicle owner thousands in repairs. With the right tools, the job can be performed with precision, resulting in a smoother ride and enhanced safety on the road.

Investing in quality tools not only aids in the immediate task but also serves as a long-term asset for ongoing vehicle maintenance.

Step-by-Step Guide to Removing and Installing Front Hub Bearings

Replacing front hub bearings is a critical maintenance task that can significantly enhance your vehicle's safety and performance. According to industry reports, approximately 30% of vehicle failures are attributed to bearing-related issues, emphasizing the importance of regular inspections and timely replacements. In 2025, following a step-by-step guide to remove and install front hub bearings can empower vehicle owners and mechanics alike, ensuring both safety on the road and optimal vehicle functionality.

To begin the removal process, safely lift the vehicle using a jack and secure it with jack stands. Remove the wheel to access the hub assembly, and then proceed to detach the brake components, which typically involve unbolting the caliper and rotor. Next, the hub nut can be removed using an appropriate socket. It’s essential to check for any signs of damage or wear on the components as they are disassembled. Professional insights suggest that a clean workspace and organized parts storage streamline the reassembly process, helping to prevent misplaced components and ensuring a smooth installation.

When installing the new hub bearing, precision is key. Utilize a bearing press tool for a snug fit, and ensure the bearing is aligned properly to avoid uneven wear. Research indicates that improper installation can lead to premature failure, with an estimated 20% increase in bearing lifespan achievable through correct installation practices. Once the bearing is securely in place, reassemble the brake components and wheel in reverse order, following the manufacturer’s torque specifications closely. This meticulous approach not only enhances vehicle performance but also contributes to the longevity of other related components.

Safety Precautions and Best Practices for Hub Bearing Replacement

When undertaking the replacement of front hub bearings in your vehicle, safety should be your top priority. According to a 2023 report from the Automotive Safety Research Institute, improper handling during hub bearing replacement can increase the risk of accidents, with over 15% of repair-related injuries attributed to negligence during maintenance. Always ensure you have the proper protective equipment, including gloves and safety glasses, to shield yourself from potential debris or fluids.

In addition to safety gear, it is essential to work in a well-lit environment and utilize appropriate tools to avoid mistakes. The National Automotive Technicians Excellence organization emphasizes that using the right tools not only ensures efficiency but also minimizes the risk of injury. Ensure that your workspace is organized, and that you have access to a sturdy lift or jack stands that are rated for the weight of your vehicle. This prevents mishaps that can lead to serious injuries.

**Tips:** Before you start, take the time to review your vehicle’s service manual for specific instructions relevant to your model. Additionally, remember to check the condition of surrounding components, as a failing hub bearing can often signal broader issues within the wheel assembly. Regular inspections can help catch these problems early, thus enhancing your vehicle's performance and safety.

Front Hub Bearing Replacement: Key Safety Precautions and Practices

Related Posts

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

Top 5 Benefits of Using High Quality Transaxle Bearings for Your Vehicle

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

What is Rv Wheel Bearings and How to Choose the Right Ones for Your Vehicle