What is a Front Axle Bearing and How to Choose the Right One

When it comes to the critical components of automotive design and function, the Front Axle Bearing often remains underappreciated despite its vital role in vehicle operation. This component is essential for ensuring smooth movement within the front axle assembly, significantly affecting handling, stability, and tire longevity. According to industry reports, over 70% of vehicle dysfunction can be traced back to improper bearing maintenance, emphasizing the necessity of understanding this component's specifications and performance characteristics.

Selecting the right Front Axle Bearing involves a comprehensive assessment of factors such as load ratings, material specifications, and compatibility with specific vehicle models. The automotive bearing market is projected to reach $12.2 billion by 2026, growing at a CAGR of 5.2%, highlighting the increasing importance of high-quality bearings in enhancing vehicle performance and safety. As vehicles become more sophisticated with advancements in technology, the selection process for Front Axle Bearings requires a blend of technical knowledge and market insight to ensure optimal functionality and longevity.

In summary, understanding what a Front Axle Bearing is and how to choose the right one is crucial for vehicle owners and professionals alike. By delving into the specifications and guidelines for selection, individuals can contribute to improved vehicle performance and durability, thereby fostering a safer driving experience.

What is a Front Axle Bearing?

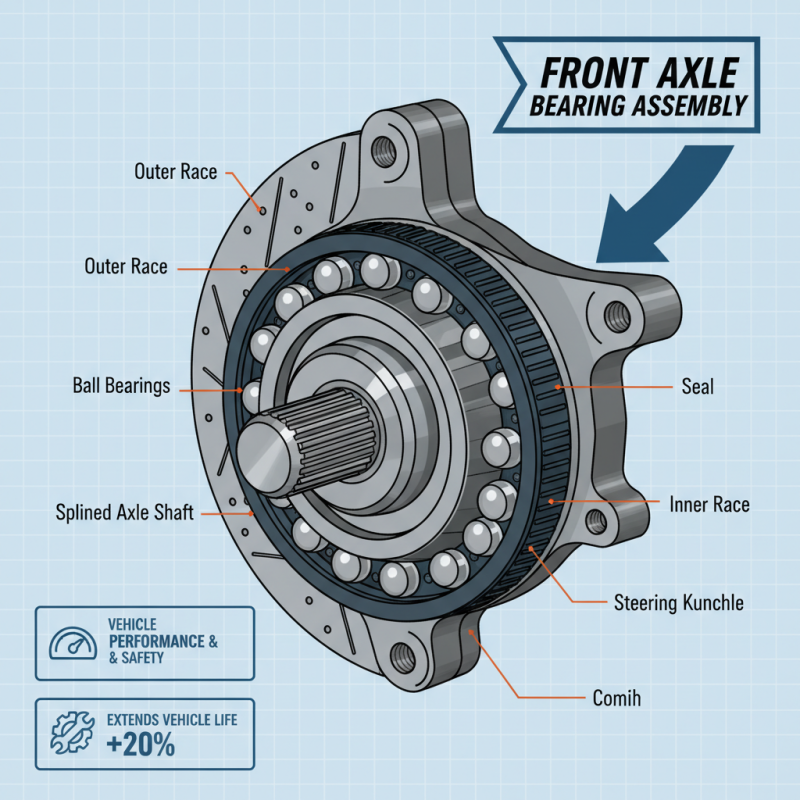

A front axle bearing is a crucial component in a vehicle's suspension and drivetrain systems. It allows for smooth rotation of the axle, supporting the weight of the vehicle while enabling efficient power transfer from the engine to the wheels. Front axle bearings are typically subjected to significant stress due to the forces exerted during driving. According to industry reports, approximately 30% of mechanical failures in vehicles are linked to bearing issues, highlighting the importance of maintaining these components effectively.

When selecting a front axle bearing, it’s essential to consider several factors, including load capacity, material composition, and environmental conditions. The bearing should be able to withstand both the radial and axial loads experienced during driving. It's also crucial to ensure that the seal quality is suitable for the vehicle's operating environment. Reports indicate that high-quality bearings significantly reduce friction and improve overall vehicle performance, which can lead to longer service intervals and enhanced fuel efficiency.

Tips: Always consult the vehicle's specifications or a professional mechanic before purchasing bearings. Regularly inspect your bearings for signs of wear, such as unusual noises or vibrations, which can indicate potential issues. Additionally, ensure proper lubrication and maintenance to extend the lifespan of your front axle bearings, as routine checks can prevent more significant problems down the road.

Importance of Front Axle Bearings in Vehicle Performance

Front axle bearings play a critical role in overall vehicle performance, impacting handling, safety, and longevity. These components support the weight of the vehicle while allowing the wheels to rotate with minimal friction. According to a report from the Automotive Aftermarket Suppliers Association (AASA), worn or damaged front axle bearings can lead to significant issues, including increased tire wear and poor alignment, ultimately affecting fuel efficiency. In fact, research indicates that proper maintenance of axle bearings can enhance a vehicle's performance and extend its service life by up to 20%.

Furthermore, the significance of high-quality front axle bearings cannot be overstated. An analysis by the Society of Automotive Engineers (SAE) shows that improper bearing selection can reduce axle assembly life by as much as 30%. The data suggests that selecting the right bearing type, taking into account load ratings, material specifications, and environmental conditions, is essential for maintaining optimal vehicle functionality. Properly maintained front axle bearings contribute to smoother ride quality and improved steering response, showcasing their importance in the complete vehicle dynamics. Therefore, awareness and understanding of front axle bearings are vital for vehicle owners and mechanics alike.

Types of Front Axle Bearings and Their Applications

Front axle bearings are critical components in the suspension system of vehicles, allowing smooth rotation of the wheels and supporting the weight of the vehicle. There are several types of front axle bearings, each suited for specific applications. The two most common types are tapered roller bearings and ball bearings. Tapered roller bearings are designed to handle both axial and radial loads, making them ideal for heavy vehicles and those that experience significant weight distribution changes. Meanwhile, ball bearings are often used in lighter vehicles due to their ability to provide lower rolling resistance, enhancing fuel efficiency.

Another type worth mentioning is the sealed bearing, which is designed to keep out moisture and debris, thus extending the lifespan of the bearing. This type is particularly beneficial for off-road vehicles that encounter harsh conditions. Additionally, there are also unitized bearings, which come pre-installed in an assembly that simplifies installation and replacement. Understanding the specific application and load requirements of your vehicle is essential when choosing the right front axle bearing type, as it can greatly impact performance and longevity.

Factors to Consider When Choosing a Front Axle Bearing

When selecting a front axle bearing, several critical factors need to be considered to ensure optimal performance and reliability. Firstly, the bearing's load rating is crucial. According to a report by the American Society of Mechanical Engineers (ASME), the load capacity should match or exceed the expected loads during operation to prevent premature failure. For example, heavy-duty applications may demand bearings with higher dynamic load ratings to accommodate greater stress, while lighter vehicles may function adequately with standard ratings.

Material selection also plays a significant role in the bearing's durability and resistance to wear. Many front axle bearings are made from high-carbon chrome steel due to its superior hardness and fatigue resistance, as noted in studies published in the Journal of Tribology. Additionally, environmental conditions must be taken into account; bearings exposed to moisture, dirt, or corrosive substances require proper sealing or should be made of corrosion-resistant materials such as stainless steel or specialized composites.

Finally, tolerances and fit are essential to ensure proper installation and function. A study by the International Organization for Standardization (ISO) indicates that precise tolerances reduce friction and enhance energy efficiency, thus extending the lifespan of the bearing. Thus, understanding these factors can lead to better decision-making and improved performance in automotive applications.

Front Axle Bearing Performance Comparison

This chart compares the performance metrics of standard and high-performance front axle bearings. Consider factors like load capacity, durability, noise level, and cost when selecting the right front axle bearing for your vehicle.

Maintenance Tips for Front Axle Bearings to Ensure Longevity

Front axle bearings play a crucial role in the smooth operation of a vehicle, supporting the weight of the axle and allowing for efficient wheel movement. To ensure the longevity of these components, regular maintenance is essential. One effective practice is to routinely inspect the bearings for signs of wear, such as unusual noises or vibrations while driving. Catching these issues early can prevent more serious damage and costly repairs.

Another important maintenance tip is to keep the axle bearings properly lubricated. Over time, grease can become contaminated or diminish, leading to increased friction and wear. Regularly checking and replenishing the lubrication can help maintain optimal performance. Additionally, it's vital to ensure that the seals are intact, preventing dirt and moisture from entering the bearing assembly, which can lead to rust and premature failure. By following these maintenance tips, drivers can extend the life of their front axle bearings and enhance the overall reliability of their vehicles.

Related Posts

-

How to Choose the Best ATV Wheel Bearings for Your Off-Road Adventure

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

Top 5 Benefits of Using High Quality Transaxle Bearings for Your Vehicle

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications