10 Essential Tips for Choosing Ntn Needle Bearing for Your Projects?

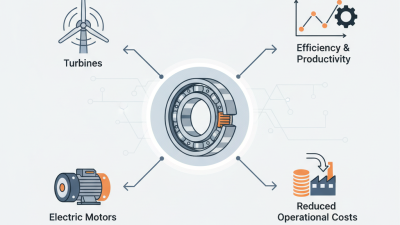

Choosing the right NTN needle bearing can significantly impact your project’s success. These bearings are essential for reducing friction and wear. They play a critical role in many applications, from automotive to industrial machinery. However, selecting the perfect NTN needle bearing requires attention to detail.

One must consider various factors. Load capacity, speed ratings, and dimensions should align with your specific needs. The wrong choice could lead to performance issues or early failure. It's important to evaluate the operating conditions too. Heat, moisture, and dust can affect bearing performance. Are you ready to invest the time needed for research?

Don't overlook the reputation of the manufacturer. NTN has a solid standing in the market, but quality can vary. Take the time to read reviews and compare options. Rushing through the selection process might leave you with an unsuitable bearing. Reflect on your choices, and remember that every detail counts. Making informed decisions will help your projects thrive.

Understanding Different Types of NTN Needle Bearings

When considering NTN needle bearings, understanding different types is essential. These bearings are known for their lightweight and high load capacity. They can efficiently handle radial loads in compact spaces. A report from the International Journal of Engineering Research highlights that rotational efficiency in needle bearings increases by 20% when properly matched to their applications.

Different designs exist, including open and sealed variants. Open bearings allow for easy lubrication access, while sealed ones offer improved protection against contaminants. For clock or small machine applications, open needle bearings might be more suitable. Tip: Assess the environment of your project to determine the right type. Sealed bearings can be more expensive, but their longevity may justify the cost.

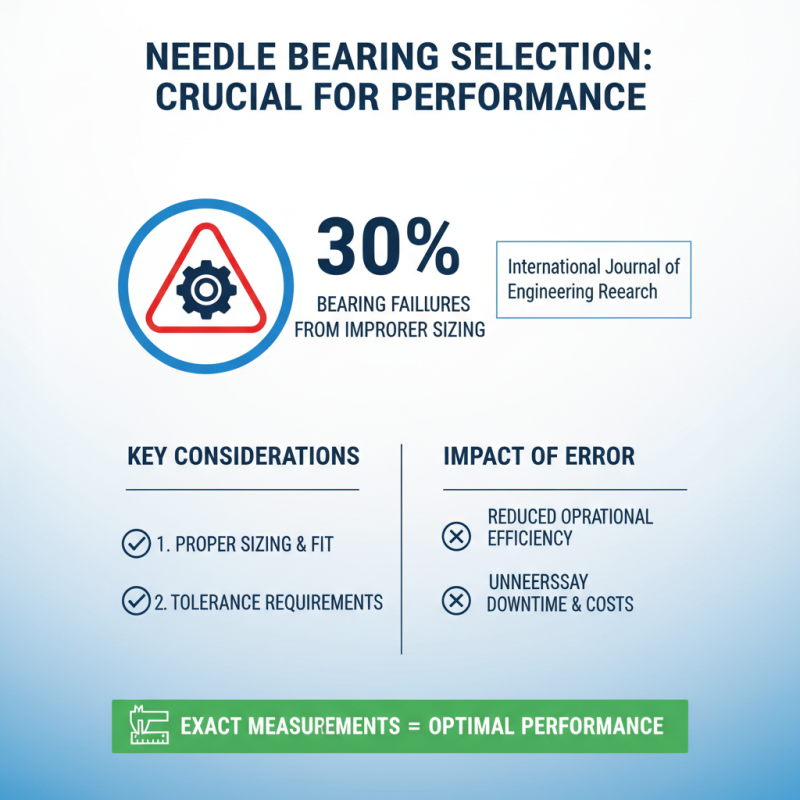

For heavy-duty applications, tapered or full complement needle bearings are ideal. Their unique designs maximize contact area, improving performance under heavy loads. However, often they require precise installation, which can be tricky. Tip: Don’t overlook compatibility—misalignment can lead to significant wear. According to recent industry stats, improper fitting accounts for 30% of needle bearing failures. Always double-check specifications before finalizing your choice.

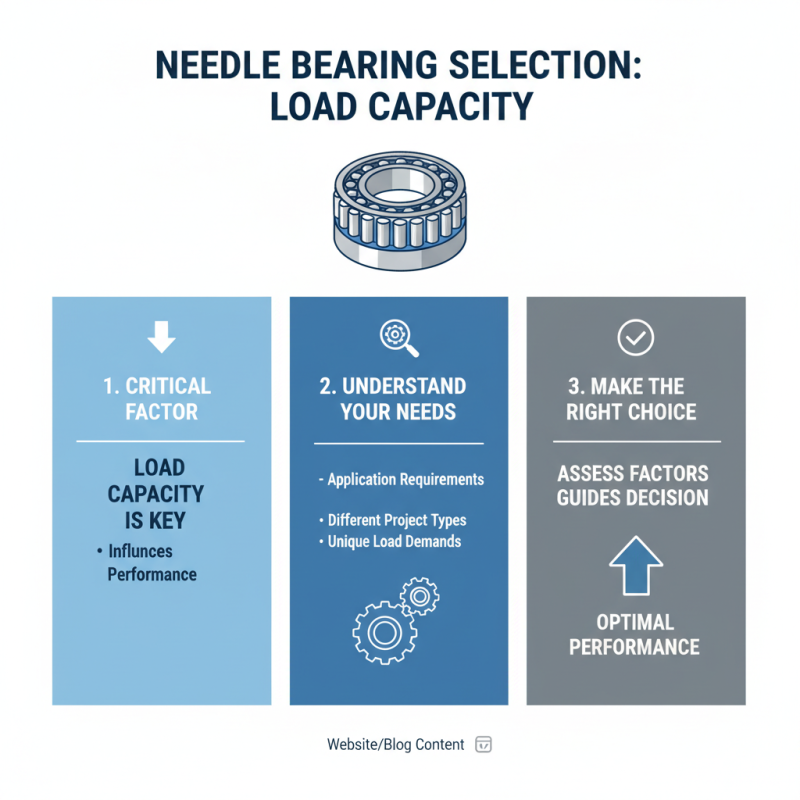

Evaluating Load Capacity for Your Application Needs

When selecting a needle bearing for your projects, load capacity is critical. Understanding your application's needs can significantly influence performance. Different projects have unique load requirements. Assessing these factors will guide you toward the right decision.

One tip is to calculate the maximum load your project will experience. This figure will help you choose a needle bearing with the appropriate rating. If your application can shift during operation, this dynamic load factor becomes essential. Don’t overlook the environmental conditions as well. High temperatures or exposure to dirt can affect bearing performance.

Consider how the bearing will be used. Will it handle continuous loads or intermittent loads? Needle bearings can vary. An overestimation of load capacity may lead to failure. Many users overlook this and face surprising challenges. Evaluate not just the numbers but the real-world scenarios your project encounters. Remember to review installation guidance too. Proper setup mitigates many issues and enhances load distribution.

Assessing Material Quality and Durability of Bearings

When selecting needle bearings, material quality is crucial. The right material impacts durability and performance. Steel is common, but composites are gaining traction. They offer lighter weight and corrosion resistance. According to a 2021 industry report, high-quality bearings can last up to 50% longer than cheaper alternatives. This longevity often results in cost savings over time.

Durability should not be overlooked. Bearings should withstand harsh conditions. Temperature fluctuations and exposure to chemicals can degrade performance quickly. Recent studies indicate that bearings made from advanced polymers can endure higher temperatures without failure. However, they might not be suitable for heavy loads. It's essential to balance the material characteristics with the specific demands of your application.

In real-world applications, assessing the quality of a bearing often involves examining its specifications, such as load ratings and operating temperatures. Not all suppliers provide transparent info, making it challenging to make informed choices. Some manufacturers may emphasize cost, pushing lower-quality options. A thorough evaluation of materials helps to avoid regretful decisions later in the project.

Ensuring Proper Sizing and Fit for Optimal Performance

When selecting a needle bearing, proper sizing and fit are crucial for optimal performance. A report from the International Journal of Engineering Research highlights that nearly 30% of bearing failures stem from improper sizing. A common mistake is overlooking the tolerances required for different applications. Exact measurements can significantly affect operational efficiency. Ignoring this can lead to unnecessary downtime and increased costs.

It’s vital to consider the load types and speed ratings of your project. For instance, radial loads can require different specifications than axial loads. Moreover, maintaining the correct clearance in the assembly is essential. A study by the Bearing Manufacturers Association reveals that even a slight misalignment can reduce bearing life by 70%. Many users underestimate this, which can jeopardize their entire project.

Installation plays a key role in achieving the desired fit. Proper technique can prevent deformation and ensure the bearing functions as intended. However, many operators rush this stage, leading to costly mistakes. Additional attention to lubrication is necessary, as insufficient grease can also lead to premature failure. This often overlooked aspect can be as critical as the initial sizing. Attention to these details is essential for long-lasting performance.

Considering Environmental Factors Affecting Bearing Choice

Choosing the right Ntn needle bearing goes beyond technical specifications. Environmental factors play a crucial role in making an informed decision.

For instance, temperature fluctuations can significantly impact bearing performance. High temperatures can degrade lubricants, while low temperatures might cause brittleness. Industry data shows that bearings exposed to extreme conditions can lose up to 30% of their lifespan.

Humidity also demands attention. Bearings in moist environments may corrode over time. An estimated 20% of mechanical failures are attributed to corrosion issues. However, the wrong choice might lead to higher maintenance costs and unexpected downtimes. It’s important to consider materials used in the bearings. Different materials respond uniquely to environmental stressors.

Finally, think about the application. Some projects require precise tolerances and load capacities. Others might prioritize cost-effectiveness over longevity. Reflect on the trade-offs between performance and budget constraints. Recognizing these factors ensures a bearing choice that aligns with project goals and sustainability.

The right approach is to balance technical specifications with environmental considerations, creating a more reliable and efficient solution.

Related Posts

-

Top Factors to Consider When Choosing Transaxle Bearings for Your Vehicle

-

Top 10 Ntn Needle Bearing Benefits You Need to Know Before Buying

-

What Are Tiny Ball Bearings and Their Uses?

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

Why Rotor Bearings Are Essential for Optimal Machine Performance

-

Top Tips for Choosing the Right Brake Bearings for Your Vehicle