How to Choose the Right Groove Bearing for Your Project?

Choosing the right groove bearing for your project can feel overwhelming. The market is vast, with numerous options available. According to the latest industry report by Bearing Tech Insights, groove bearings account for over 25% of all bearing sales globally. This demonstrates their importance in various applications, from automotive to industrial machinery.

Expert John Smith, a seasoned engineer in the bearing industry, states, “Selecting the correct groove bearing can make or break a project.” This highlights the critical nature of this decision. Understanding load capacity, material type, and environmental factors is crucial.

Many projects falter due to a lack of detailed assessment. In some cases, engineers assume a one-size-fits-all approach. However, each application has unique needs. For instance, consider temperature ranges and resistance to corrosion. Skipping these details could lead to premature bearing failure. Reflecting on these factors can empower you to make informed choices in groove bearings.

Understanding the Basics of Groove Bearings and Their Applications

Groove bearings are essential components in many mechanical systems. They play a critical role in providing support and facilitating smooth motion. These bearings come in various designs, each tailored to specific applications. Understanding their types and uses is crucial for making an informed choice.

The most common groove bearings are spherical and cylindrical. Spherical bearings allow for movement in multiple directions. They are ideal for applications with misalignment. Cylindrical bearings provide linear motion and are often used in sliding applications. The choice between them depends on the project requirements. Consider load capacity, speed, and environmental conditions when making your selection.

However, not all groove bearings fit every need. Some may wear out quickly in harsh environments. Improper sizing can lead to failures. It's important to assess your application carefully. Analyze the workload, cycle frequency, and any potential contaminants. Choosing the wrong bearing can affect performance and longevity. Always reflect on your decision to ensure success in your project.

How to Choose the Right Groove Bearing for Your Project?

| Bearing Type | Load Capacity (lbs) | Operating Temperature Range (°F) | Speed Rating (RPM) | Material |

|---|---|---|---|---|

| Standard Groove Bearing | 1500 | -20 to 180 | 3000 | Steel |

| Heavy-Duty Groove Bearing | 3000 | -40 to 220 | 2000 | Stainless Steel |

| Plastic Groove Bearing | 800 | -20 to 120 | 5000 | Plastic Composite |

| High-Speed Groove Bearing | 1000 | -30 to 150 | 6000 | Ceramic |

Identifying Key Factors in Groove Bearing Selection

Choosing the right groove bearing for your project involves several crucial factors. Start with the operating conditions. Consider the temperature ranges and environments where the bearing will be used. High temperatures can affect lubrication, while humidity may lead to corrosion.

Next, assess the load requirements. Bearings must support the weight they encounter. This includes dynamic and static loads. Think about the bearing's size. A larger bearing might be necessary when heavy loads are present, but ensure it fits within your design constraints.

Materials play a significant role as well. Metal, plastic, and ceramics each have pros and cons. Metal offers strength, but it may corrode. Plastic can resist moisture but may not handle high loads effectively. Balancing these factors is not easy. Each project presents unique challenges. You may not always find the ideal bearing. This requires careful consideration and sometimes multiple trials before arriving at a satisfactory solution.

Evaluating Material Options for Groove Bearings

When selecting groove bearings, material choice plays a crucial role in performance. Common materials include steel, bronze, and polymer. Steel bearings offer strength and durability. However, they may suffer from corrosion. Bronze provides excellent wear resistance, making it suitable for high-load applications. Yet, it can be more expensive and heavier.

Polymer materials are gaining popularity. They are lightweight and resistant to wear. Data from recent industry studies indicate that polymer bearings can reduce friction by up to 40% compared to traditional materials. This can lead to energy savings and prolonged equipment life. However, they may not handle extreme temperatures as well as metal counterparts.

Ultimately, understanding the project's requirements is vital. Factors like load, speed, and environment guide material selection. Balancing these criteria is often a challenge. Material properties must align with the operational demands. Sometimes, the best choice isn't the most obvious one. Experimental trials can provide insights into performance limitations and long-term behavior.

Material Options for Groove Bearings

This chart illustrates the load capacity of different material options for groove bearings, helping you to make an informed decision for your project.

Assessing Load and Speed Requirements for Your Project

Choosing the right groove bearing involves understanding load and speed requirements. These factors significantly impact the performance and lifespan of your project. Assessing the type of load your application will bear is crucial. Is it static, dynamic, or shock load? Each type requires a different bearing approach.

When considering speed, think about the rotational velocity. Higher speeds increase heat buildup, affecting bearing life. It's important to match the bearing's speed rating to your project needs. Opt for a bearing that can handle peaks in speed without compromising performance.

**Tips:** Always measure your load accurately. Underestimating can lead to premature failures. If unsure, consulting with an expert can offer valuable insights. Also, remember to check the environmental conditions. Factors like humidity and temperature can influence your bearing selection. Don’t rush this decision; take your time to evaluate all aspects thoroughly.

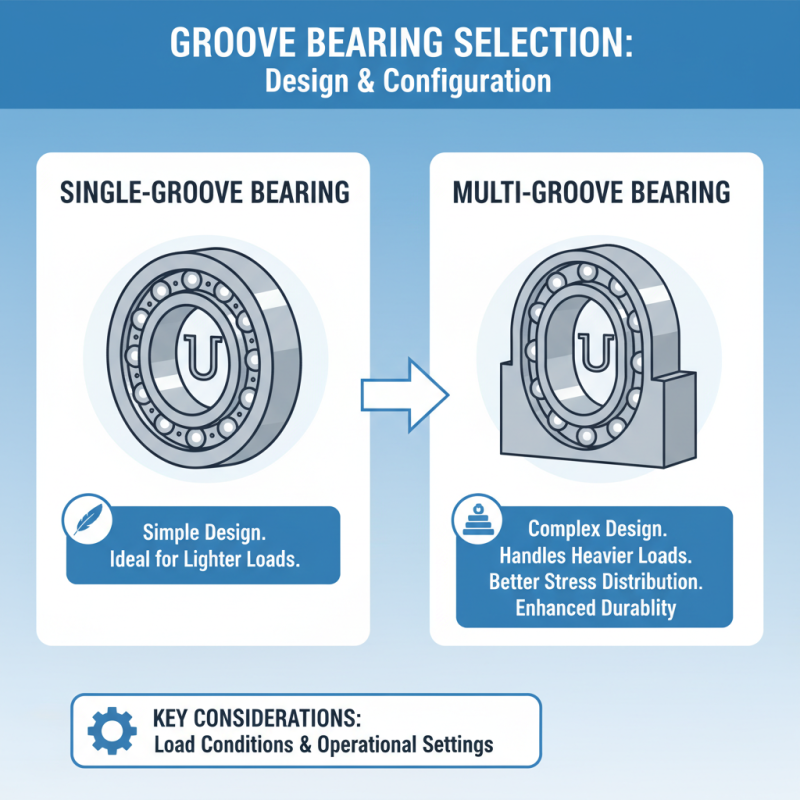

Choosing the Right Design and Configuration for Groove Bearings

When selecting a groove bearing, design and configuration are crucial. Different designs cater to varying load conditions and operational settings. The simplest form is a single-groove bearing, ideal for lighter loads. However, for heavier applications, consider multi-groove options. They distribute stress better and enhance durability.

The configuration can change performance significantly. For instance, narrow groove bearings can accommodate tighter spaces but may not handle heavy loads effectively. Conversely, wider grooves provide better load distribution but require more room. Always assess the environment. Temperature and humidity can affect the material choice. Ignoring these factors can lead to early bearing failure.

Reflections on design choices are essential. Why select a specific configuration? Is it truly suitable? A mismatch can result in inefficiencies. Common mistakes include underestimating load requirements or overlooking alignment issues. Testing and adjustments along the way can help improve outcomes and ensure the right fit for your project.

Related Posts

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

Why Rotor Bearings Are Essential for Optimal Machine Performance

-

How to Choose the Right Cushion Bearing for Your Project Needs

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

What is a Front Axle Bearing and How to Choose the Right One

-

Top Car Wheel Bearing Types You Should Know About?