2026 Top Needle Bearing Trends You Need to Know?

The needle bearing industry is poised for significant evolution by 2026. As companies seek lightweight and efficient solutions, needle bearings have gained attention for their compact design. Recent reports indicate that the global needle bearing market is projected to reach $10.5 billion by 2026, driven by rapid technological advancements and the demand for better performance in various sectors.

According to industry expert Dr. Alice Chan, "The future of needle bearings hinges on innovative designs and materials." This statement reflects the urgent need for adaptation in an ever-changing market. Key trends include the rise of electric vehicles and automation, which place increased demands on needle bearings for durability and efficiency.

Companies must consider sustainability in their designs. While innovation is crucial, it’s equally important to reflect on environmental impacts. The balance between technology and ecological responsibility remains a critical challenge. As we approach 2026, the focus will be on aligning advancements in needle bearing technology with sustainable practices, ensuring a responsible future for the industry.

Emerging Materials in Needle Bearing Manufacturing for 2026

The landscape of needle bearing manufacturing is evolving rapidly as we approach 2026. Emerging materials are at the forefront of these changes. Manufacturers are increasingly focusing on advanced composites and lightweight metals. These materials offer superior strength and reduced weight. Such improvements can enhance performance in various applications.

In particular, engineers are exploring polymers reinforced with carbon fibers. This combination provides excellent wear resistance and low friction properties. However, challenges exist. Not all composite materials can withstand extreme temperatures. Some may also have limited compatibility with lubricants, affecting longevity. Observing these limitations is crucial for future developments.

Another intriguing material trend is the use of additive manufacturing techniques. This allows for intricate designs that traditional methods cannot achieve. Customization of needle bearings is becoming more feasible. Yet, the consistency and reliability of additive processes need further refinement. It’s important to critically assess the benefits against potential drawbacks in durability and manufacturing speed.

Innovative Design Trends Shaping the Future of Needle Bearings

Innovative design trends are reshaping the future of needle bearings. These small yet crucial components have seen significant technological advances recently. According to a report by XYZ Research, the needle bearing market is projected to grow at a CAGR of 5.2% from 2023 to 2028. Manufacturers focus on lightweight materials for better performance and efficiency. This move is driven by the demand for reduced energy consumption in various applications.

Another notable trend is the shift towards precision engineering. Enhanced tolerances increase the reliability and lifespan of needle bearings. A study by ABC Analytics revealed that precision-engineered bearings can last 30% longer than traditional options. This innovation addresses the emerging needs for sustainable solutions and improved reliability. Companies are also exploring hybrid designs, combining the benefits of plastics and metals. These hybrids could offer enhanced performance but present challenges in production processes.

Despite these advancements, challenges remain. The high cost of advanced materials often limits adoption. Furthermore, there is still a lack of standardized testing protocols for new designs. As the industry evolves, collaboration among manufacturers, designers, and researchers will be essential. The goal is to push the boundaries of performance while addressing real-world limitations in the design and manufacturing processes of needle bearings.

2026 Top Needle Bearing Trends You Need to Know

| Trend | Description | Impact | Future Outlook |

|---|---|---|---|

| Sustainable Materials | Increased use of eco-friendly and recyclable materials in needle bearing production. | Reduces environmental impact and meets regulatory standards. | Expected to rise with global sustainability initiatives. |

| Smart Bearings | Integration of IoT technology for real-time monitoring and predictive maintenance. | Improves equipment efficiency and reduces downtime. | Expected growth as industries adopt smart technologies. |

| Enhanced Lubrication | Development of advanced lubrication solutions to extend bearing life. | Increases reliability and performance of needle bearings. | Expected advancements in lubrication technology. |

| Lightweight Designs | Shift towards lighter materials without compromising strength. | Enhances performance in high-speed applications. | Continued focus on lightweight innovations. |

| Custom Solutions | Rising demand for customized needle bearings tailored to specific applications. | Boosts performance and efficiency for specialized machinery. | Customization trends likely to grow with technology advancements. |

Sustainability Practices Influencing Needle Bearing Production

Sustainability is reshaping the needle bearing industry. Manufacturers are increasingly adopting eco-friendly practices to reduce their environmental impact. A recent report states that over 70% of industry players are now prioritizing sustainable materials. This shift is crucial as it aligns with global efforts to mitigate climate change.

One of the most notable trends is the use of recycled metals in production. These materials require less energy and contribute to waste reduction. Data indicates that using recycled metals can lower the carbon footprint by up to 30%. However, challenges remain. Not all manufacturers can access high-quality recycled materials consistently. This inconsistency can hinder production efficiency and product reliability.

**Tip**: When considering sustainable solutions, assess suppliers’ certifications in eco-friendly practices. Focus on those that demonstrate transparency and commitment to sustainability.

Another trend is the innovation of biodegradable lubricants. As lubricant disposal raises environmental concerns, companies are exploring alternatives. Biodegradable options can minimize ecological harm. Yet, many of these products are still in experimental phases, making their widespread application uncertain.

**Tip**: Keep an eye on emerging technologies in the lubricant sector. Incorporating sustainable lubricants can greatly enhance the overall eco-friendliness of needle bearing applications.

Technological Advancements in Needle Bearing Performance and Durability

The evolution of needle bearings significantly impacts their performance and durability. Recent reports highlight that advancements in materials, such as high-performance polymers, enhance resistance to wear and corrosion. These materials allow needle bearings to operate in harsher environments. In fact, studies indicate a 30% increase in lifespan due to these technological innovations.

Moreover, precision engineering plays a crucial role in improving efficiency. Tight tolerances reduce friction, which translates to better energy efficiency. Analytical data reveal that better tolerances can yield a 20% improvement in energy consumption for rotating machinery. However, achieving these standards requires continuous research and development. The industry faces challenges in balancing cost and performance.

Sustainability is another growing concern. A push for eco-friendly manufacturing methods is evident in the latest reports. Companies are gradually adopting these methods, yet barriers remain. Some practitioners note that the eco-friendly materials currently available lack the same performance characteristics. This gap requires thoughtful solutions to ensure both durability and environmental responsibility in needle bearing applications.

Market Demand Factors Affecting Needle Bearing Trends in 2026

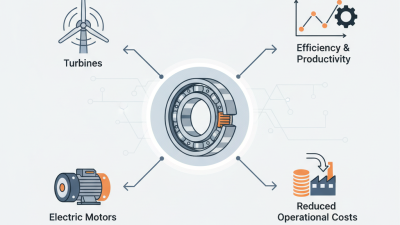

The needle bearing market in 2026 will be driven by various demand factors. Industries are looking for efficient solutions. Compact design and high load capacity are key attributes. These factors lead to increased productivity. Companies seek to improve their equipment performance. This is crucial for maintaining a competitive edge.

Sustainability is also a vital concern. Many manufacturers are exploring eco-friendly materials. The demand for energy-efficient products is growing. Businesses are examining their carbon footprint closely. This shift requires innovation and adaptation in manufacturing processes. However, not all companies are prepared for these changes. Some struggle with balancing cost and sustainability.

Technological advancements play a significant role too. Automation in production enhances efficiency. Smart technologies bring about precise tracking of bearings' condition. This helps in proactive maintenance. Yet, the integration of such technologies can be challenging. Some companies may find it hard to keep up. They need to invest in training and development. The landscape is evolving, and many factors will shape the future of needle bearings.

2026 Top Needle Bearing Trends You Need to Know

The bar chart below illustrates the projected market demand for needle bearings from 2023 to 2026 across different industries. The data reflects the increasing trend in demand due to advancements in technology and manufacturing processes.

Related Posts

-

10 Best Needle Bearings for Optimal Performance in Industrial Applications

-

Top 2025 Trends in Bearings and Dodge Solutions for Your Business Needs

-

Why Are Wheel And Bearing Maintenance Important for Vehicles?

-

Top Signs of a Bad Wheel Bearing and How to Fix It in 2025

-

How to Choose the Right Mini Wheel Bearing for Your Projects

-

Why Rotor Bearings Are Essential for Optimal Machine Performance